item no.:

PA12-NA-LGFPayment:

Discussedproduct origin:

ChinaColor:

Natural color or Customizedshipping port:

XiamenLead Time:

2-10 working daysWhat Is It?

PA12 composite, reinforced with continuous long glass fibers for enhanced toughness, dimensional stability, and low moisture absorption. Engineered for demanding applications where flexibility, chemical resistance, and long-term mechanical performance are essential.

Technology Behind the Strength

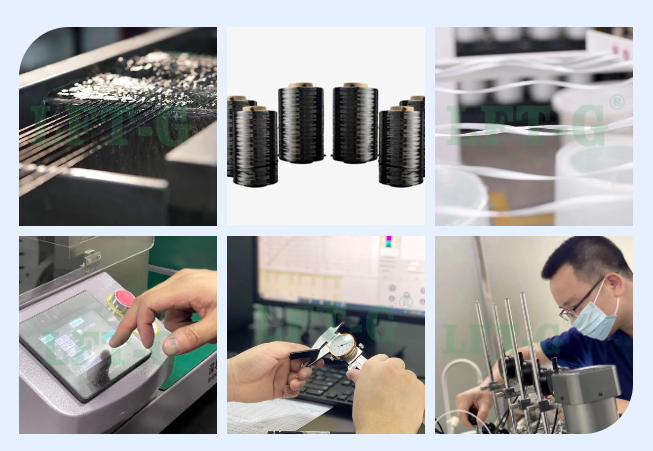

1. Continuous Fiber Architecture

Compared to short fiber materials, our PA12-LGF utilizes long glass fibers aligned during molding. These fibers form a continuous reinforcement network within the polymer matrix, significantly improving impact strength, fatigue resistance, and structural integrity over time.

2. Advanced Pultrusion Process

Each pellet is produced using a controlled pultrusion process, ensuring consistent fiber length (typically 12–25 mm), uniform fiber distribution, and optimal bonding between fiber and resin. This results in more predictable mechanical properties and reduced warpage.

Where It Works Best

Tailored for applications where traditional PA12 or other engineering plastics fall short under mechanical or environmental stress.

Automotive:

Fuel system components, connectors, low-temperature flexible parts

Industrial:

Pipe fittings, pneumatic system parts, flexible brackets, housings

Energy & Electrical:

Cable glands, insulating housings, battery module parts

Sporting Goods & Consumer Applications:

Bike components, high-performance gear, wear-resistant parts

3D Printing & Prototyping:

Filament and pellet feedstock for FGF or pellet-based 3D printing with excellent toughness and flexibility

Performance Highlights

Tailored for Your Needs

We don’t believe in one-size-fits-all. Our PP-LGF compounds can be modified to suit:

Flame retardancy (94-V0)

UV stabilization for outdoor use

Color-matched aesthetics

Conductive or anti-static performance

...

Why Choose Us?

Engineering-Driven. Customer-Focused. Globally Connected.

With over 20 years of expertise in long fiber composite solutions, we work closely with OEMs, molders, and manufacturers around the world. Whether you need performance consistency, supply stability, or rapid development support, we deliver results that go beyond material supply.

Ready to Explore?

Connect with our technical team for:

Free Sample Requests

Custom Formulation Consultations

Full Technical Datasheets

On-site Application Support