item no.:

HPP-NA-LGFPayment:

T/T or L/C (other payment ways also can be diproduct origin:

Xiamen, ChinaColor:

Original color (also can be customized)shipping port:

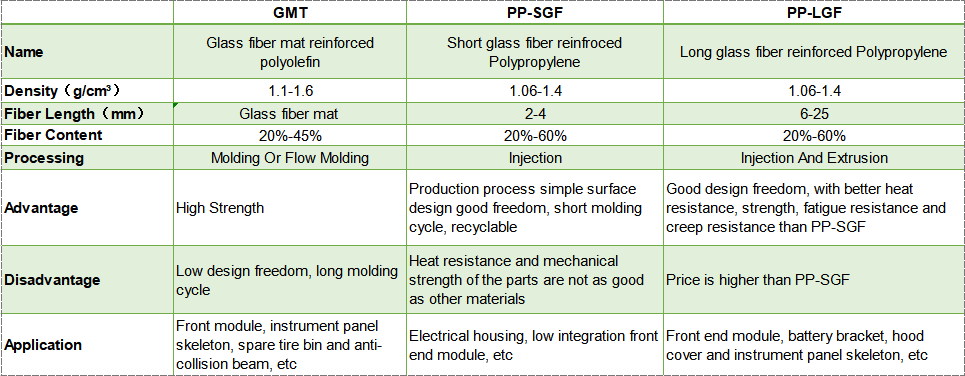

Xiamen, ChinaHPP-LGF (Long Glass Fiber Reinforced Homopolymer Polypropylene) is a high-performance thermoplastic composite designed for structural and load-bearing applications where conventional PP materials fall short.

Homopolymer polypropylene (PP-H or HPP) is produced by polymerizing a single propylene monomer. Due to its highly regular molecular structure, HPP exhibits high crystallinity, resulting in good strength and rigidity.

However, the absence of ethylene units leads to poor impact resistance, especially at low temperatures. As a result, unmodified HPP tends to be brittle and unsuitable for demanding structural applications.

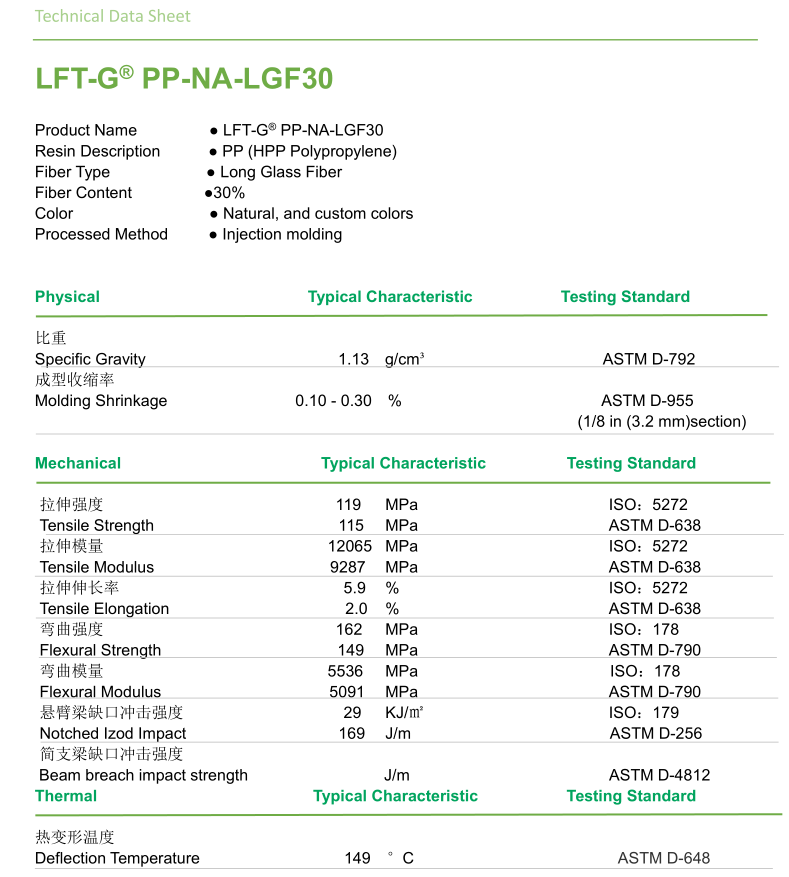

By reinforcing HPP with long glass fibers, the mechanical and thermal limitations of conventional PP-H can be significantly improved. HPP-LGF materials combine the chemical resistance and cost efficiency of polypropylene with the structural strength of long glass fiber reinforcement.

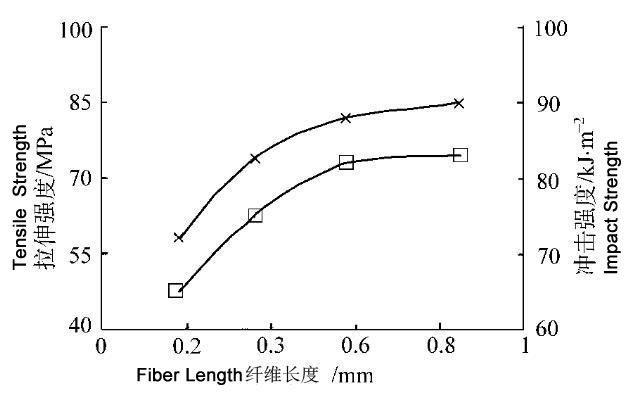

Compared with short glass fiber reinforced materials, long glass fiber compounds deliver significantly superior mechanical performance. LGF materials are especially suitable for large components and structural parts.

Toughness can be improved by 1–3 times, while tensile strength and stiffness typically increase by 50–100% compared with short fiber reinforced plastics.

Long glass fiber reinforced composites provide solutions when conventional reinforced plastics cannot meet performance requirements or when metal replacement is desired.

By forming a continuous long-fiber internal skeleton network, LGF composites significantly improve the mechanical properties and durability of engineering polymers while reducing overall system cost. Performance is maintained across a wide range of environmental conditions.

Xiamen LFT Composite Plastic Co., Ltd specializes in LFT & LFRT materials, including Long Glass Fiber (LGF) and Long Carbon Fiber (LCF) series. Our thermoplastic LFT materials are suitable for LFT-G injection molding, extrusion, and LFT-D molding.

Fiber length can be customized from 5 to 25 mm according to customer requirements. Our continuous impregnation reinforced thermoplastics have passed ISO 9001 and IATF 16949 certifications, and our products are protected by multiple national trademarks and patents.