item no.:

PA12-NA-LCF30Payment:

T/T or L/C (other payment ways also can be diproduct origin:

Xiamen, ChinaColor:

Original color (also can be customized)shipping port:

Xiamen, ChinaLead Time:

7-15 days after shipmentPolyamide 12

PA12, nylon 12, also known as polydodecalactam and polylactam, is a long carbon chain nylon.

There are non-polar methylene groups in nylon 12, and the number is large, which makes the flexibility of nylon 12 molecular chain larger; the amide group in nylon 12 is polar, and the cohesion energy is large, and it can form hydrogen bonds between molecules, which makes the arrangement of molecules more regular. Therefore, the crystallinity of nylon 12 is high, and the strength is also higher. Nylon 12 (PA12) has low water absorption, good low temperature resistance, good air tightness, excellent alkali resistance, grease performance, medium resistance to alcohols and inorganic dilute acids and aromatics, good mechanical properties and electrical properties, and is a self-extinguishing material.

1) Density

The relative density of nylon 12 is only 1.01-1.03, which is the smallest among all engineering plastics, which has a certain effect on reducing the mass of the car and lowering the fuel consumption. If compared by unit volume, nylon 12 has advantages in price and performance.

2) Melting point

The melting point of nylon 12 is 172-178℃, which is slightly lower than that of nylon 11, and it can fully meet the working temperature requirement of automobile fuel and air brake pipes.

3)Water absorption

As we all know, the biggest drawback of nylon products is the large water absorption, and it is difficult to ensure the dimensional stability. However, due to the increase of methylene molecules in nylon 12, the influence of hydrophilic groups is greatly reduced, therefore, nylon 12 has the lowest water absorption rate among nylon products, which reduces the change of performance and size of products caused by water absorption, which makes nylon 12 have great advantages. After water absorption, the tensile strength of nylon 12 decreases very little, while nylon 66 and nylon 6 have great changes.

4) Impact strength

Impact strength is an important technical index, and it is especially important for nylon 12 tubes that are often exposed to air. Nylon 12 at -20 ℃ and -40 ℃ according to the standard test, no fracture phenomenon, fully meet the requirements of use. Nylon 12 impact resistance is very good.

5)Low temperature performance

Nylon 12 has the lowest brittleness temperature of -70 degrees Celsius, so it can be widely used for parts with low temperature resistance.

6) Flexibility

The effect of plasticizers on the physical properties of nylon 12 is concentrated on the elastic modulus of the resin. There are three basic types of nylon 12 resins, the main difference between them is the different plasticizer content and the formation of different flexibility. As the content of plasticizer extractable components increases, the elastic modulus of the resin decreases.

7)Low abrasion and low friction properties

Nylon 12 has excellent low-wear and low-friction properties and self-lubricating properties, so the frictional noise of Nylon 12 products is very low.

8)Fuel resistance

In the automobile, the current use of oxygenated fuel, high aromatic fuel and alcohol mixed fuel will lead to the decomposition of many hose materials. Only nylon 11, nylon 12 and fluorocarbon elastomers have been tested for use in this environment. Under the action of motor fuels, all nylons dissolve, resulting in dimensional changes, especially in methanol-containing gasoline, where nylons containing large amounts of amide groups such as nylon 6 dissolve much more than nylons containing small amounts of amide groups such as nylon 12 %. It is found that the fuel containing 15% methanol has a great effect on nylon.

9) Resistant to zinc chloride solution

Zinc chloride will appear in the environment under the car. Under certain temperature and humidity, the salt on the road reacts with galvanized steel or zinc-containing primer to form a small amount of zinc chloride. Zinc chloride is highly corrosive, but Nylon 12 is highly resistant to zinc chloride solutions. Ozone aging, UV exposure, temperature conditions, etc., can bring varying degrees of damage to parts and reduce service life. Since nylon 12 does not contain the + 2 3 2 + unsaturated double bond, which is susceptible to ozone attack, it does not suffer from ozone aging.

In addition, the high crystallinity of nylon 12 and its high melting temperature make it more stable in terms of heat resistance, and the addition of heat stabilizers increases its heat resistance exponentially. When exposed to sunlight, its energy can cause the chemical bonds of organic materials to break. The bonding energy of C-H, C-O and C-N bonds in nylon 12 is so large that UV light is not enough to break them, but only the C-C bonds with smaller bonding energy; therefore, after adding appropriate anti-aging agents to the raw materials, the UV resistance of nylon 12 is excellent.

Polyamide 12 - Long carbon fiber

In the modified engineering plastics industry, long fiber reinforced composites are composites made from long carbon fibers, long glass fibers, etc., through a series of special modification methods. The biggest characteristic of long fiber composites is that they have superior performance that the original materials do not have. If we classify them according to the length of the reinforcing materials added, they can be divided into: long fiber, short fiber and continuous fiber composites.

Long carbon fiber composite material is a kind of long fiber reinforced composite material, which is a new fiber material with high strength and high modulus fiber. LCF carbon fiber composite material shows high strength along the fiber axis direction, and has high strength and light weight, and has a full range of mechanical properties such as density, specific strength and specific modulus that are incomparable with other materials, which is a new material with excellent mechanical properties and many special functions. It is a new material with excellent mechanical properties and many special functions.

Corrosion resistance: LCF carbon fiber composite materials have good corrosion resistance and can adapt to the harsh working environment.

UV resistance: the ability to resist UV is strong, and the products are less damaged by UV.

Abrasion and impact resistance: the advantage of comparing with general materials is more obvious.

Low density: lower density than many metal materials, can achieve the purpose of light weight.

Other properties: such as reducing warpage, improving rigidity, impact modification, increasing toughness, electrical conductivity, etc.

LCF carbon fiber composites have higher strength, higher rigidity, lower weight, and excellent electrical conductivity compared with glass fiber.

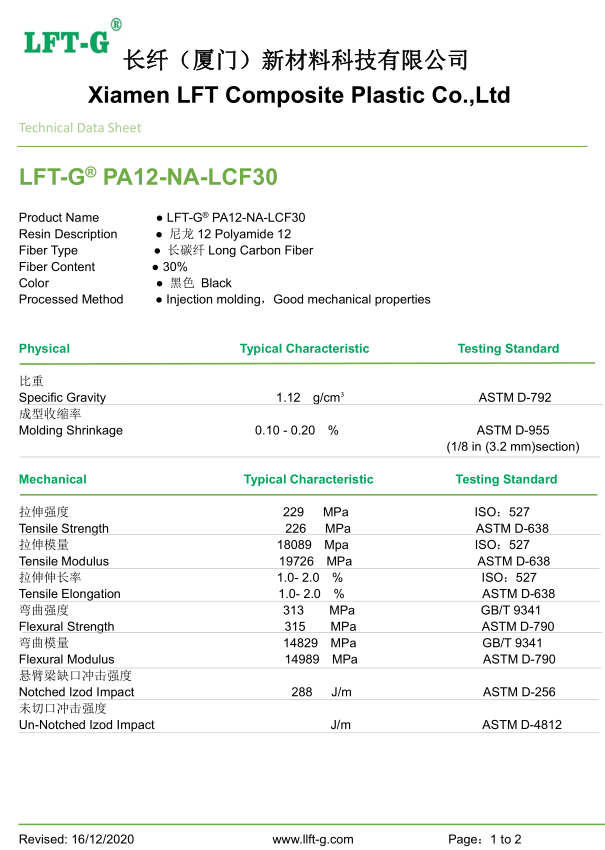

Datasheet for reference

Application

LFT long carbon fiber composites have high specific strength and stiffness, and are resistant to corrosion, fatigue, high temperature and low coefficient of thermal expansion, etc. At home and abroad, LCF carbon fiber composites are widely used in rockets, missiles, military aircraft, individual protection and other military industries. Compared with conventional materials, long carbon fiber composites can enable military equipment performance to be continuously improved, such as the ability to reduce the weight of warships by 20%-40%.

LCF carbon fiber composite materials have low density, good chemical resistance, excellent performance and other characteristics, has gradually become the preferred modified engineering plastics in the home appliance industry, its use accounts for about 30% and is on the rise. And home appliances are increasingly pursuing intelligence and personalization, and the modified performance requirements for the application of materials are also higher. Therefore, it is expected that the long carbon fiber composite material is chosen by the home appliance industry.

One of the key components of the wind turbine is the blade, the production of wind turbine blade to take into account the aerodynamic impact, technical process and the structure of composite materials and other factors, blade length and wind power generator power proportional relationship. Blade although the overall quality of the proportion is not large, but is the highest cost of the fan components, accounting for 15-20%, so the production of blade material selection is critical.

Tests

Details

| Number | Length | Color | Fiber specification | Package | MOQ | Port of Loading | Delivery time |

| PA12-NA-LCF | 6-25mm | Natural or customized | 20%-60% | 20kg/bag | 20kg | Xiamen Port | 7-15 days after shipment |

Exhibitions of 2023

Frequently asked questions

1. Is there a uniform reference data for carbon fiber product performance?

The performance of specific carbon fiber filaments is fixed, such as Toray's carbon fiber filaments, T300, T300J, T400, T700, etc. There are a series of parameters that can be traced. However, there is no uniform standard to measure the carbon fiber composite products. Firstly, the different models of raw materials selected will lead to different performance of the products, and then the different selection of substrate and product design will lead to different performance of the products. In addition to some common carbon fiber tube, carbon fiber plate and other conventional parts, most of the carbon fiber products have to be sampled before production, through the test of the sample to determine whether the performance of the product is in line with the expected standard of use, and as a base point, so as to carry out mass production and use.

2. Are carbon fiber composite products very expensive?

The price of carbon fiber composite products is closely related to the price of raw materials, the level of technology and the quantity of products. The higher the performance of the raw material, the more expensive it is, such as the carbon fiber PEEK thermoplastic material used in orthopedics. Of course, the more complex the manufacturing process, the greater the working time and workload, and the increased production costs. However, the larger the order quantity, the lower the cost per product. In the long run, the superior performance of carbon fiber will prolong the life of the product, reduce the number of maintenance, and is also very beneficial to the reduction of the cost of use.

3. Are carbon fiber composite products toxic?

Carbon fiber composites are made of carbon fiber filaments mixed with ceramics, resins, metals and other substrates, and are generally not toxic. For example, the above-mentioned PEEK material is made of food-grade resin, which is very compatible with the human body and is not only harmless to the human body, but also becomes a more ideal material for orthopedic surgery because of its high strength and elastic modulus close to the bone cortex. Carbon fiber medical bed plate, which will be in contact with many patients' bodies every day, will not have adverse effects on the human body; on the contrary, it will be of great help to the accuracy of medical diagnosis.

4. Are all carbon fiber composite products black with woven pattern?

The color and pattern of carbon fiber composite products can be customized. The pattern is determined by the pre-layered design, and the default color is black, but the color can be changed by painting later. In addition, you can print your own design or logo on the carbon fiber products.

5. What is the difference between thermoset and thermoplastic carbon fiber composites?

Thermoset carbon fiber composites are mainly based on the role of curing agent in the curing process. While thermoplastic carbon fiber composite products mainly rely on cooling down to achieve shaping. Thermoplastic carbon fiber composites are not as popular as thermoset carbon fiber composites, mainly because they are expensive and are generally used in high-end industries. Thermoset carbon fiber composites are difficult to recycle due to the limitation of the resin matrix itself, and are generally not considered; thermoplastic carbon fiber composites can be recycled, and can be made twice as long as they are heated to a certain temperature.