-

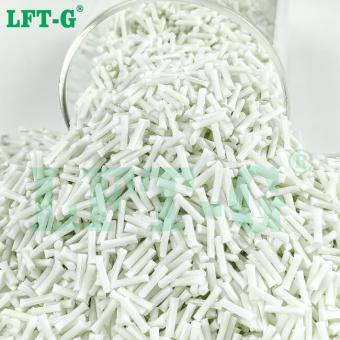

Nylon Materials LFT Carbon Fiber Modified Polymer PelletsPA6 Long Carbon Fiber Reinforced Composite is a high-performance engineering material composed of a polyamide 6 (PA6) matrix reinforced with long carbon fibers. It delivers outstanding mechanical strength, rigidity, and fatigue resistance, while maintaining excellent dimensional stability and thermal performance.

- materials nylon

- pa cf filament

- pa plastic material

- different kinds of carbon fiber

- strength carbon fiber

- long fiber

Tags :

-

PPS High Temperature Resistance with Glass FiberPPS long carbon fiber reinforced materials combine excellent mechanical strength, high thermal stability, and outstanding chemical resistance. They are ideal for precision parts used in high-temperature, corrosive, or high-stress environments.

- pps resin suppliers

- long fiber compounds

- carbon fiber reinforced thermoplastic

- lft g for automobile market

- applications of polymers in aerospace engineering

- carbon thermoplastic

Tags :

-

High Performance Long Fiber ABS Lightweight Metal Replacement SolutionGlass fiber reinforced ABS modified plastics have many advantages, including excellent strength and stiffness, excellent heat resistance, good chemical resistance, low water absorption, good electrical insulation and stable performance. These advantages make it have a wide range of application prospects in many fields, and can meet the needs of different industries for high-performance materials.

- Reinforced ABS plastic

- High-performance plastic compounds

- Automotive ABS plastic parts

- Industrial ABS components

- ABS GF

- long fiber composites

Tags :

-

High Performance Long Fiber PLA Lightweight Metal Replacement SolutionLong Fiber Reinforced PLA (LFR-PLA) is an engineering plastic that combines long glass fibers with polylactic acid (PLA) resin. PLA itself is an environmentally friendly thermoplastic, known for its biodegradability. However, it has limited mechanical properties, such as strength, toughness, and heat resistance. By incorporating long glass fibers, the performance of PLA is significantly improved, making it suitable for demanding applications.

- PLA Green materials

- PLA recycled plastics

- composite materials in renewable energy market

- glass filled PLA filament

- long fiber filling materials

- Polylactic acid

Tags :

-

LFT PBT Polybutylene terephthalate Long Glass Fiber filled CompositesOne of the remarkable features of PBT-GF is its excellent dimensional stability. The presence of glass fibers greatly reduces the material's tendency to expand or contract under varying temperature conditions. This property ensures that PBT GF retains its shape and size, making it suitable for applications that demand tight tolerances and precise dimensions.

- pbt fibers

- pbt plastics

- pbt resin

- long fiber thermoplastics

- fiber glass fiber

- carbon fiber glass fiber

Tags :

-

High Performance PPS Engineering Plastics Long Glass Fiber Plastic CompoundsLFT®PPS-NA-LGF is glass reinforced PPS compound, which is filled with glass fiber based on the PPS resin. The characteristic of PPS compounds includes good mechanical properties, high rigidity, high creep resistance, high temperature resistance.

- composites for ev battery

- long fiber thermoplastics metal replacement

- polymers used in aircraft

- types of fibers in composite materials

Tags :

-

PLA Recycled Materials Green Plastics Long Glass Fiber Plastic CompoundsPLA-LGF can be processed using conventional plastic processing techniques like injection molding and extrusion, offering good adaptability in manufacturing. It is widely used in industries like automotive, consumer electronics, 3D printing, and eco-friendly packaging due to its combination of high performance and sustainability.

- gfrp price per kg

- types of fibers in composites

- wind turbine composites

- wholesale glass fiber

- glass fiber material properties

Tags :

-

Nylon 6 Thermoplastic Plastics Long Carbon Fiber Plastic CompoundsNylon 6 is a suitable material for injection molding. The resulting molded nylon parts possess great strength, as well as chemical and temperature resistance.view more

-

Glass Fiber Reinforced PP Pellets High StrengthPolypropylene, also known as PP or polypropene, is a polyolefin or saturated polymer. It is a low-density thermoplastic with good resistance to heat. Other characteristics of PP include: chemical resistance, elasticity, toughness, fatigue resistance, and electrical insulation capability.

- long glass fiber reinforced polypropylene

- wind turbine composite materials

- pp-lgf30

- oem polypropylene fiber

- long fiber thermoplastic

- fiber forms

Tags :

-

LFT Modified Polyamide 66 filled long glass fiber compoundsLong glass fiber reinforced nylon 66 has better reinforcement effect and dimensional stability, and the rigidity, tensile, bending, impact resistance and fatigue resistance of the manufactured products are better, and the service life is longer.

- Low warpage electronic appliance

- self owing pa66 pellets thermoplastic resin

- high strength and high toughness reinforced pa66 pellets

- best long glass fiber pa66 lgf30 granules

- PA66 6 twin screw lgf pellets

- Long Fiber PA66 granules Application

Tags :

-

High Temperature Resistant PPS Long Glass Fiber Polymer PelletsPPS lengthened glass fiber (LGF) composite material has the advantages of high toughness, low warpage, fatigue resistance, and good product appearance. It can be used in water heater impellers, pump casings, joints, valves, chemical pump impellers and casings, cooling water impellers and Shells, home appliance parts, etc.

- PPS engineering plastic supplier

- Automotive PPS plastic parts

- PPS for industrial structural components

- PPS glass fiber reinforced material

- LFT granules

Tags :

e-mail

e-mail English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português العربية

العربية 日本語

日本語 한국의

한국의 中文

中文