item no.:

PLA-NA-LGFPayment:

Discussedproduct origin:

ChinaColor:

Natural color or Customizedshipping port:

XiamenLead Time:

2-10 working daysWhat Is PLA GF?

Our PLA (Polylactic Acid) composite reinforced with continuous long glass fibers (LGF) offers enhanced mechanical strength, improved thermal stability, and superior dimensional accuracy compared to neat PLA. Designed for applications seeking a balance between bio-based sustainability and high-performance structural properties.

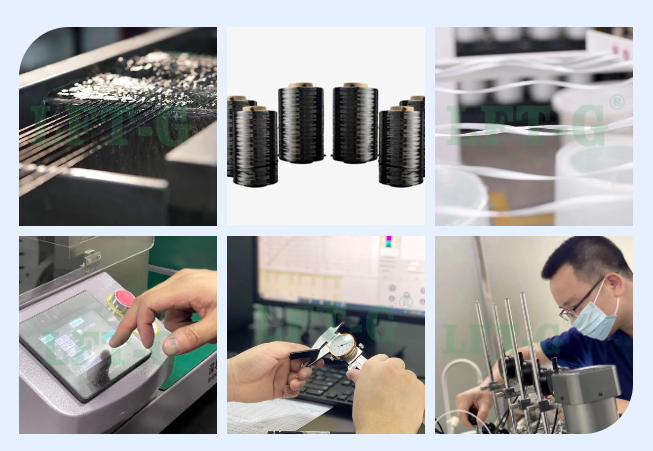

Technology Behind the Strength

Long Glass Fiber Reinforcement

Unlike conventional short fiber composites, our PLA-LGF materials incorporate long glass fibers (typically 12–25 mm) oriented and uniformly dispersed during processing. This continuous fiber network substantially improves tensile strength, stiffness, impact resistance, and fatigue durability, overcoming the inherent brittleness of pure PLA.

Advanced Compounding and Pelletizing

Utilizing precision compounding and pelletizing techniques, the long glass fibers maintain their length and alignment within the PLA matrix, ensuring consistent mechanical performance and processability in injection molding and extrusion.

Balanced Thermal and Environmental Properties

While PLA has a moderate heat resistance (typically up to ~60–80°C), the reinforcement with long glass fibers enhances its thermal deformation temperature and dimensional stability under load. Being bio-based and biodegradable, PLA composites provide a more sustainable alternative for applications where environmental impact is a concern.

Chemical Resistance and Moisture Sensitivity

PLA offers moderate resistance to some chemicals but is sensitive to hydrolysis and moisture over time. The addition of long glass fibers improves structural integrity but does not significantly enhance chemical resistance; hence, application environments should consider moisture exposure and chemical compatibility.

Where It Works Best

Optimized for applications where biodegradability, sustainability, and mechanical performance are all important:

Consumer Goods:

Durable and lightweight components for electronics housings, sporting goods, and consumer appliances requiring higher strength and stiffness than neat PLA.

Packaging:

High-performance packaging components that benefit from enhanced mechanical stability while maintaining biodegradability.

Automotive Interiors:

Non-structural interior parts that demand improved dimensional stability, moderate heat resistance, and lightweight design.

Medical Devices:

Biocompatible components and housings that leverage PLA’s bio-based origin combined with enhanced mechanical properties.

Performance Highlights

Tailored for Your Needs

We don’t believe in one-size-fits-all. Our PP-LGF compounds can be modified to suit:

Flame retardancy (94-V0)

UV stabilization for outdoor use

Color-matched aesthetics

Conductive or anti-static performance

...

Why Choose Us?

Engineering-Driven. Customer-Focused. Globally Connected.

With over 20 years of expertise in long fiber composite solutions, we work closely with OEMs, molders, and manufacturers around the world. Whether you need performance consistency, supply stability, or rapid development support, we deliver results that go beyond material supply.

Ready to Explore?

Connect with our technical team for:

Free Sample Requests

Custom Formulation Consultations

Full Technical Datasheets

On-site Application Support