-

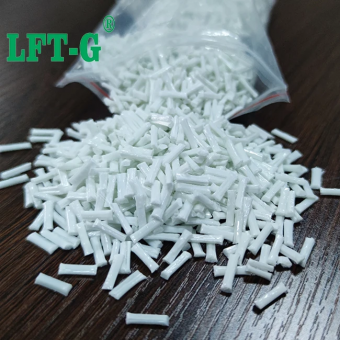

Engineering-Grade MXD6 LFT Material for Automotive & ElectronicsMXD6 Nylon - MXD6 is a kind of crystalline polyamide resin, which is synthesized by the condensation of m-benzoylamine and adipic acid. The advantages of nylon MXD6 1. In a wide range of temperature, maintain high strength, high rigidity 2. High thermal deformation temperature and small thermal expansion coefficient 3. Low water absorption rate, small size change after water absorption, less mechanical strength reduction 4. Forming shrinkage rate is very small, suitable for precision forming processing 5. Excellent coating, especially suitable for high temperature surface coating 6. Oxygen, carbon dioxide and other gases also have excellent barrier Application of MXD6 in plastic modification industry MXD6 can be combined with fiberglass, carbon fiber, mineral, and/or advanced fillers for use in fiberglass reinforced materials containing 50-60% and for exceptional strength and stiffness. Even when filled with high glass content, its smooth, resin-rich surface produces a fibre-free high gloss surface, ideal for painting, metal-plating, or creating naturally reflective shells. 1. suitable for high liquidity of thin wall It is a very fluid resin that can easily fill thin walls as thin as 0.5 mm thick even when the glass fiber content is as high as 60%. 2. Excellent surface finish A resin-rich perfect surface has a highly polished appearance, even with a high glass fiber content. 3. High strength and stiffness The tensile and flexural strength of MXD6 is similar to that of many cast metals and alloys with the addition of 50-60% glass fiber reinforced material. 4. good dimensional stability At ambient temperatures, the linear expansion coefficient (CLTE) of MXD6 glass fiber composites is similar to that of many cast metals and alloys. Strong reproducibility due to low shrinkage and the ability to maintain tight tolerances (length tolerances as low as ± 0.05% if properly formed). Datasheet Tested by our own lab, for reference only. laboratory & Warehouse Frequently asked questions 1. How to choose the fiber content of the product? Is the larger product suitable for higher fiber content material? A. This is not absolute. The content of glass fiber is not more is better. The suitable content is just to meet the requirements of each products. 2. Can products with appearance requirements be made of long-fiber materials? A. The main feature of LFT-G thermoplastic long glass fiber and long carbon fiber is to show the mechanical properties. If the customer has bright or other requirements for the appearance of the products, it needs to be evaluated in combination with specific products. 3. Are there any special process requirements of long carbon fiber injection molding products? A. We must consider the requirements of long fiber for the injection molding machine screw nozzle, mold structure and injection molding process. Long fiber is a relatively high cost materiaql, and need to evaluate the cost performance problem in the selection process. Main materials Why choose us 1. Integration of R&D, production and sales 2. Customized products, one-to-one pre-sales and after-sales service 3. Passed a number of system certifications, and product quality is stable 4. Five warehousing centers nationwide to meet customers' high-volume needs 5. Testing is available in an independent laboratory with technical experts with 30 years of experience 6. Sold globally to Asia, Europe, North America, Middle East

- high performance MXD6

- MXD6 composite for drone frames

- MXD6 replacement for metal

- long fiber reinforced thermoplastics

- high stiffness thermoplastics for UAV

- China MXD6 long glass fiber supplier

Tags :

-

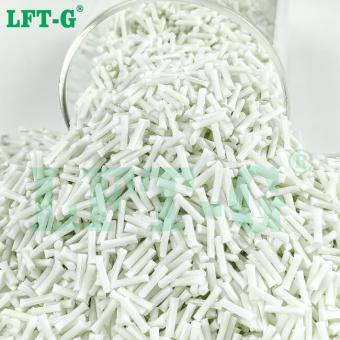

PBT Composite Pellets with 20-60% Long Glass Fiber ContentPBT Long Glass Fiber Reinforced Material offers excellent dimensional stability, high strength, and outstanding chemical resistance. It is ideal for structural components requiring durability, heat resistance, and long-term mechanical performance.

- polybutylene terephthalate resin

- pbt plastic

- plastic resin manufacturer

- glass fiber reinforced plastic

- engineering plastic

- long glass fiber

Tags :

-

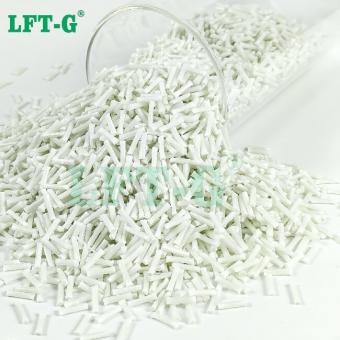

Glass Fiber Reinforced PP Pellets High StrengthPolypropylene, also known as PP or polypropene, is a polyolefin or saturated polymer. It is a low-density thermoplastic with good resistance to heat. Other characteristics of PP include: chemical resistance, elasticity, toughness, fatigue resistance, and electrical insulation capability.

- long glass fiber reinforced polypropylene

- wind turbine composite materials

- pp-lgf30

- oem polypropylene fiber

- long fiber thermoplastic

- fiber forms

Tags :

-

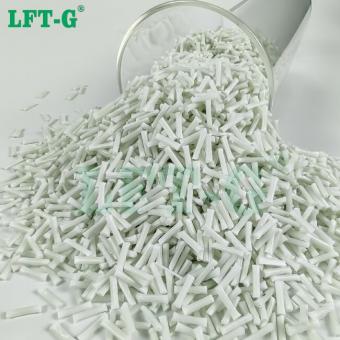

Glass Fiber Reinforced Nylon 12 Resin Pellets Injection MoldingPa12 gf is produced by mixing nylon 12 compounds with glass fibers in an extruder or a compounding machine. The mixture is then granulated into pellets that can be used for injection molding or other processing methods. Pa12 gf can also be produced by adding glass fibers directly to the injection molding machine during the molding process.

- composites non-destructive testing

- plastic granules price per kg

- long glass fiber reinforced polypropylene market

- pa12 resin

- pa12 gf20

- nylon pa12

Tags :

-

LFT Polypropylene PP filling long glass fiber 20%-60% high performance thermoplastic resinIn the manufacturing industry, in order to match some output products that require higher quality than usual, manufacturers will mix into PP plastic with glass fiber or glass beads. These two different forms of glass enhancement are inherently tough and durable, so when mixed, glass-filled polypropylene materials become lighter and stronger.view more

-

LFT-G Polyamide6 nylon6 filling long glass fiber orginal color for automotive partsThe main advantages of nylon 6 are its stiffness and resistance to abrasion. Moreover, this material has excellent impact strength, wear resistance, and electrical insulating properties. Nylon 6 is a highly elastic and fatigue-resistant material, meaning it will return to its original proportions after being distorted by tension. This polyamide is non-toxic and can be combined with glass or carbon fibers to increase performance.

- Polyamide 6 composite properties

- lgf thermoplastic resin good price

- High impact PA6 instead metal plastic

- injection molding plastic gf30 filter

- pa6 filling long glass fiber customized

- Reinforced plastic lightweight compounds

Tags :

-

LFT Modified Polyamide 66 filled long glass fiber compoundsLong glass fiber reinforced nylon 66 has better reinforcement effect and dimensional stability, and the rigidity, tensile, bending, impact resistance and fatigue resistance of the manufactured products are better, and the service life is longer.

- Low warpage electronic appliance

- self owing pa66 pellets thermoplastic resin

- high strength and high toughness reinforced pa66 pellets

- best long glass fiber pa66 lgf30 granules

- PA66 6 twin screw lgf pellets

- Long Fiber PA66 granules Application

Tags :

-

LFT-G modified ABS compounds Long Glass Fiber for automotive partsABS also has good dimensional stability and can be easily machined or drilled after molding.

- Modified material lft injection molding

- ABS compounds long glass fiber

- lgf injection mold abs for engineering

- reinforced material abs filling lgf

- ABS-LGF30 thermoplastic resin

- Thermoplastic resin ABS

Tags :

-

Xiamen LFT-G HDPE filling long glass fiber thermoplasitc reinforced compoundsHigh-density polyethylene (HDPE), also called polyethylene high-density (PEHD), is a thermoplastic polymer made from the monomer ethylene. When used for HDPE pipes, it is sometimes called "alkathene" or "polythene." With a high strength-to-density ratio, High-density polyethylene (HDPE) is used to produce corrosion-resistant piping. In addition, HDPE is commonly recycled.

- HDPE filling lgf20

- lgf hdpe composite materials

- reinforced hdpe plastic resin

- long glass fiber hdpe

- Thermoplastic hdpe lgf

- hdpe resin compounds

Tags :

-

LFT-G Polyamide6 nylon6 filling long glass fiber orginal color for automotive partsThe main advantages of nylon 6 are its stiffness and resistance to abrasion. Moreover, this material has excellent impact strength, wear resistance, and electrical insulating properties. Nylon 6 is a highly elastic and fatigue-resistant material, meaning it will return to its original proportions after being distorted by tension. This polyamide is non-toxic and can be combined with glass or carbon fibers to increase performance.view more

-

LFT China Manufacturer PPA Long Glass Fiber Reinforced PolymersPPA long glass fiber composites are high-performance thermoplastic materials that combine the durability and strength of glass fiber reinforcement with the superior properties of PPA engineering plastics, making them ideal for demanding industrial applications.

- PPA long glass fiber composite Polyphthalamide

- high-performance PPA polymer

- glass fiber reinforced thermoplastics

- PPA engineering plastic materials

- durable thermoplastic composites

- industrial PPA reinforced polymer

Tags :

-

LFT-G modified ABS compounds Long Glass Fiber for automotive partsABS injection molding refers to the process of injecting molten ABS plastic into a mold at high pressures and temperatures. There are many ABS injection molding applications as it is a widely used plastic and can be found in the automotive, consumer product, and construction industries to name a few.

- ABS Long Glass Fiber Reinforced Polymer

- ABS long fiber reinforced

- China manufacturer ABS GF fiber reinforced

- High-performance engineering plastic ABS composite

- Natural color abs materials with filler

Tags :

e-mail

e-mail English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português العربية

العربية 日本語

日本語 한국의

한국의 中文

中文