item no.:

PA12-NA-LCFPayment:

Discussedproduct origin:

ChinaColor:

Natural color or Customizedshipping port:

XiamenLead Time:

2-10 working daysWhat Is PA12 LCF?

Our PA12 (Polyamide 12) composite reinforced with continuous long carbon fibers (LCF) delivers outstanding mechanical strength, excellent impact resistance, superior dimensional stability, and remarkable chemical resistance. Engineered for high-performance applications requiring lightweight structural parts that maintain stability under mechanical loads, thermal cycling, and harsh environments.

Technology Behind the Strength

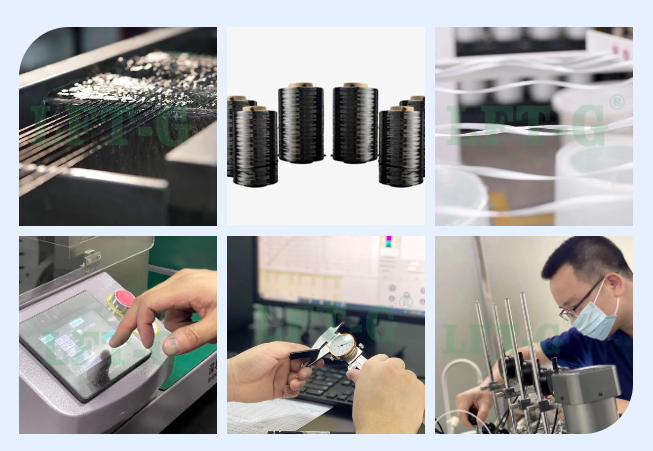

Continuous Long Carbon Fiber Reinforcement

Unlike short fiber composites, our PA12-LCF materials feature long carbon fibers (typically 12–25 mm) carefully aligned and embedded during compounding and molding. This continuous fiber network forms a rigid internal skeleton, significantly enhancing tensile strength, flexural modulus, impact resistance, and fatigue life, far beyond short fiber composites.

Advanced Compounding & Pultrusion Techniques

Through precision pultrusion and compounding processes, long carbon fibers are uniformly dispersed within the PA12 matrix, ensuring excellent fiber-matrix adhesion and minimal fiber breakage. This provides consistent mechanical performance and reliable part quality across production batches.

Excellent Thermal and Chemical Resistance

The PA12 matrix exhibits superior resistance to fuels, oils, solvents, and a range of chemicals, along with continuous use temperatures up to ~120–150°C (248–302°F). Combined with long carbon fibers, PA12-LCF components maintain mechanical integrity even in demanding environments.

Superior Dimensional Stability and Creep Resistance

PA12’s low moisture absorption, combined with long carbon fiber reinforcement, delivers ultra-low thermal expansion, high rigidity, and excellent creep resistance — critical for precision components and load-bearing applications.

Where It Works Best

Optimized for applications requiring lightweight design, chemical resistance, and excellent mechanical performance:

Automotive & Transportation:

Fuel system components, brackets, and housings requiring chemical resistance, dimensional stability, and fatigue endurance.

Industrial Equipment:

Load-bearing parts, housings, and connectors that operate under repeated mechanical stress and exposure to chemicals.

Consumer & Sports Products:

Durable, lightweight parts for high-end sports equipment or specialty consumer products where mechanical strength and dimensional stability are essential.

Medical & Laboratory Equipment:

Chemical-resistant housings and components that demand high precision, reliability, and lightweight design.

Performance Highlights

Tailored for Your Needs

We don’t believe in one-size-fits-all. Our PP-LGF compounds can be modified to suit:

Flame retardancy (94-V0)

UV stabilization for outdoor use

Color-matched aesthetics

Conductive or anti-static performance

...

Why Choose Us?

Engineering-Driven. Customer-Focused. Globally Connected.

With over 20 years of expertise in long fiber composite solutions, we work closely with OEMs, molders, and manufacturers around the world. Whether you need performance consistency, supply stability, or rapid development support, we deliver results that go beyond material supply.

Ready to Explore?

Connect with our technical team for:

Free Sample Requests

Custom Formulation Consultations

Full Technical Datasheets

On-site Application Support