item no.:

PA12-NA-LGFPayment:

Discussedproduct origin:

ChinaColor:

Natural color or Customizedshipping port:

XiamenLead Time:

2-10 working days

The main advantages of nylon 6 are its stiffness and resistance to abrasion. Moreover, this material has excellent impact strength, wear resistance, and electrical insulating properties. Nylon 6 is a highly elastic and fatigue-resistant material, meaning it will return to its original proportions after being distorted by tension. This polyamide is non-toxic and can be combined with glass or carbon fibers to increase performance. The absorption capacity of the material grows in direct proportion to the quantity of moisture it absorbs. The high affinity of nylon 6 for some dyestuffs allows for more dyeing diversity, with the potential for brighter, deeper patterns. A form of long glass-filled Nylon known as PA66-LGF employs polyamide 66 (PA66) as the basic compounds. Nylon 66 or polyhexamethylene adipamide are other names for PA66. Compared to PA6-LGF, PA66-LGF offers greater strength, stiffness, creep, and heat resistance. Additionally, it offers higher dimensional stability and a reduced moisture absorption rate. Long Glass fiber percentage in PA66-LGF range from 20% to 60% and can also be PA66 20 LGF, PA66 30 LGF, PA66 40 LGF or PA66 50 LGF. Strength and rigidity increase with increasing glass fiber content, while toughness and impact resistance decrease.What is pa12 gf20?

Pa12 gf20 is a thermoplastic material that belongs to the nylon family. Nylon is a synthetic polymer that can be melted and molded into different shapes and forms. Nylon has many variants, such as nylon 6, nylon 6/6, nylon 11, and nylon 12. Each variant has different characteristics and properties depending on the number and arrangement of carbon atoms in its molecular structure.

Pa12 gf20 is based on nylon 12, which has 12 carbon atoms in each repeating unit of its polymer chain. Nylon 12 is also known as polyamide 12 or pa12. It is a semi-crystalline material that has a high melting point (180°C) and a low moisture absorption rate (0.5%). It also has good resistance to chemicals, abrasion, and impact.

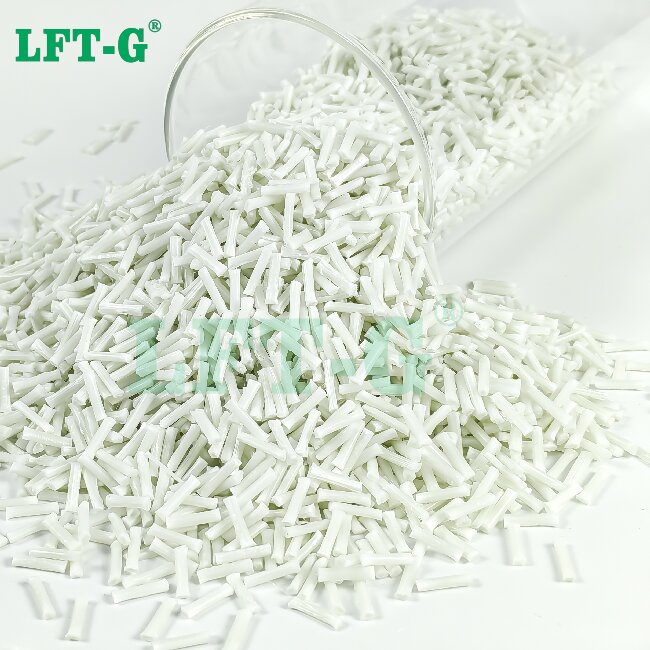

Pa12 gf20 is a modified version of nylon 12 that has been reinforced with 20% glass fibers by weight. Glass fibers are thin strands of glass that are added to the compounds to improve its strength, stiffness, and dimensional stability. Glass fibers also reduce the shrinkage and warping of the material during cooling and processing.

Pa12 gf20 is produced by mixing nylon 12 compounds with glass fibers in an extruder or a compounding machine. The mixture is then granulated into pellets that can be used for injection molding or other processing methods. Pa12 gf20 can also be produced by adding glass fibers directly to the injection molding machine during the molding process.

25kg moisture-resistant bags

Note: Values vary based on customized formulations. Full TDS provided upon request.

| Property | Value |

|---|---|

| Density | ~1.48 g/cm³ |

| Tensile Strength | 235 MPa |

| Flexural Modulus | 15048 GPa |

| HDT | 254 °C |

| Carbon Fiber Content | 40% |

Full TDS and test curves will be provided after formulation confirmation.

Structural & functional components such as luggage frames, chassis supports, and interior structural parts.

Housings, support structures, and functional load-bearing parts.

Internal frames, casings, and load-bearing components.

Frames, trusses, and other high stiffness-to-weight elements.

Xiamen LFT Composite Plastics Co., Ltd.

Global Leading Supplier of Long Fiber Reinforced Thermoplastics

Email: sale02@lfrtplastic.com · Website: www.lft-g.com · Address: No.55 Hongxi South Road, Torch High-tech Zone (Xiangan) Industrial Park. Xiamen 361000 · Phone: +86-13950095727

© Xiamen LFT Composite Plastics Co., Ltd.

All rights reserved.