Fiber specification: 20%-60%

Product feature: High strength, High toughness and durability

Fiber specification: 20%-60%

Product feature: High strength, High toughness and durability

item no.:

PA12-NA-LGFPayment:

T/T or L/C (other payment ways also can be diproduct origin:

Xiamen, ChinaColor:

Original color (also can be customized)shipping port:

Xiamen, ChinaPA12, also known as Nylon 12, Polydodecamide, or Polylauractam, is a semi-crystalline thermoplastic with long carbon chain structure. It combines excellent mechanical properties with low water absorption, high dimensional stability, chemical resistance, and toughness. PA12 is lightweight, easy to process, and highly durable.

Compared with PA11, PA12 is cost-effective due to its raw material (butadiene) being only one third the price of castor oil, yet it can replace PA11 in most applications. Its versatility makes it suitable for automotive fuel lines, air brake hoses, submarine cables, 3D printing, and more.

PA12 features a flexible molecular chain due to its high content of non-polar methylene groups. Strong hydrogen bonding ensures high crystallinity and strength. The material offers excellent low-temperature resistance, airtightness, alkali and oil resistance, medium resistance to alcohols and dilute acids, self-extinguishing properties, and superior mechanical and electrical performance.

PA12 is widely applied across industries thanks to its low water absorption, high dimensional stability, chemical resistance, and excellent toughness. Key application areas include:

Ideal for fuel lines, clutch lines, vacuum brake lines, air brake lines, battery coolant lines, and their fittings. PA12 ensures lightweight, safe, and reliable automotive fluid systems.

Used in flexible risers, gas pipes, linings, and steel pipe coatings onshore and offshore. Excellent low-temperature performance and weather resistance make it ideal for subsea oil, gas delivery, and communication cables (-50 ~ 70℃).

PA12 powder offers high flowability, low static, low water absorption, moderate melting point, and precise dimensional control. Excellent fatigue resistance and toughness make it ideal for engineering-grade 3D printed parts.

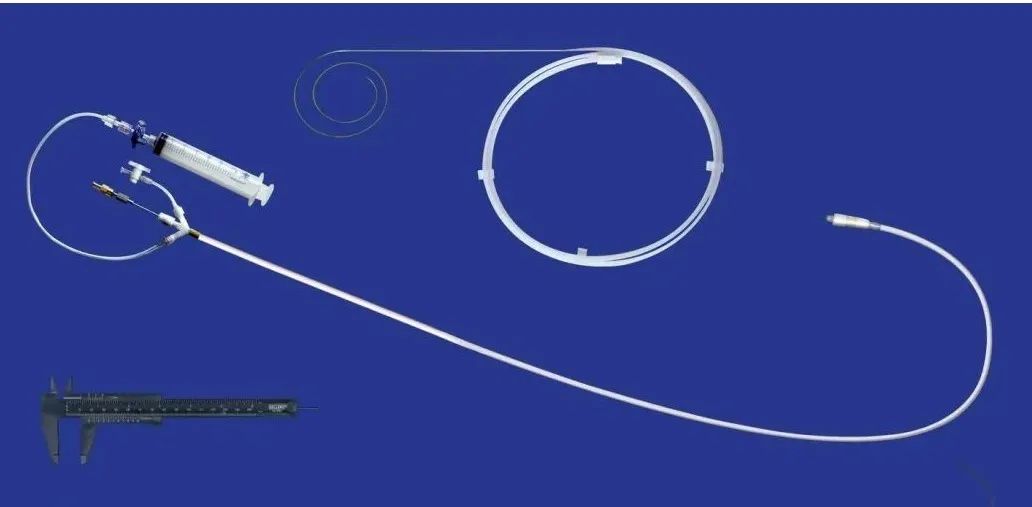

Ideal for catheters and medical tubing due to high bursting pressure, flexibility, chemical resistance, body fluid compatibility, and non-toxicity. Compliant with FDA and EU medical standards.

Used in eyewear frames, sports equipment, and other fatigue-resistant daily products.

Used to coat metal surfaces for high friction and wear resistance. Applications include dishwasher bowl holders, outdoor furniture, and other coated metal parts to prevent corrosion and extend service life.

Xiamen LFT Composite Plastics focuses on LFT & LFRT products, including Long Glass Fiber (LGF) and Long Carbon Fiber (LCF) series. Our thermoplastic LFT materials can be used for injection molding (LFT-G), extrusion, and compression molding (LFT-D). Fiber lengths from 5–25mm can be customized according to customer requirements.

Our long-fiber reinforced thermoplastics are ISO9001 & 16949 certified and protected by multiple national patents and trademarks.

Related Tags :