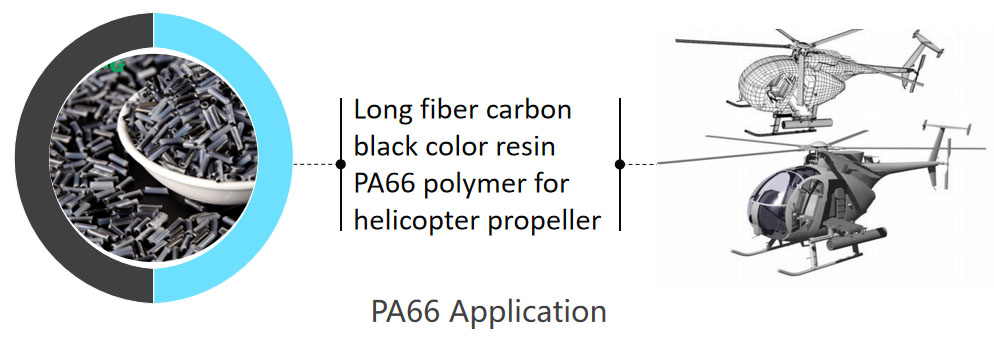

Nylon 66 high performance PA66 long carbon fiber composite materials for aerospace fileds

What is PA66 plastic? Polyadipyladipylenediamine, commonly known as nylon -66, is a thermoplastic resin, generally made from adiponic acid and hexadipamine condensation. Insoluble in general solvents, only soluble in m-cresol, etc. High mechanical strength and hardness, rigidity. It can be used as engineering plastics, mechanical accessories such as gears, lubricating bearings, instead of non-ferrous metal materials to make machine shells, automotive engine blades, and can also be used to make synthetic fibers. PA66 plastic raw material is translucent or opaque opalescent crystalline polymer, with plasticity. Density 1.15g/cm3. Melting point 252℃. Embrittlement temperature -30℃. Thermal decomposition temperature is greater than 350℃. Continuous heat resistance 80-120℃, balanced water absorption rate of 2.5%. Resistant to acid, alkali, most aqueous inorganic salts, alkyl halides, hydrocarbons, esters, ketones and other corrosion, but easy to phenol, formic acid and other polar solvents. It has excellent wear resistance, self lubricity and high mechanical strength. But the water absorption is larger, so the dimensional stability is poor. What is Long Carbon Fiber? In the modified engineering plastics industry, long fiber reinforced composite material refers to long carbon fiber, long glass fiber, aramid fiber or basalt fiber and polymer matrix, through a series of special modification methods to produce composite materials. The biggest characteristic of long fiber composites is that they have superior properties that the original materials do not have. If they are classified according to the length of the added reinforcement materials, they can be divided into long fiber, short fiber and continuous fiber composites. As mentioned in the beginning, long carbon fiber composite material is a kind of long fiber reinforced composite material, which is a new fiber material with high strength and high modulus fiber. LCF carbon fiber composite exhibits high strength along the fiber axis, and has the characteristics of high strength and light weight. It has the comprehensive mechanical properties such as density, specific strength and specific modulus that are incomparable to other materials. It is a new material with excellent mechanical properties and many special functions. What are the properties of Long Carbon fiber? Corrosion resistance: LCF carbon fiber composite material has good corrosion resistance, can adapt to harsh working environment; Uv resistance: strong ability to resist UV, products by UV damage problem is small; Wear resistance and impact resistance: compared with the general material advantage is more obvious; Low density: lower than the density of many metal materials, can achieve the purpose of lightweight; Other properties: such as reducing warpage, improving rigidity, impact modification, increasing toughness, electrical conductivity and so on. Compared with glass fiber, LCF carbon fiber composite has higher strength, higher rigidity, lower weight, and excellent electrical conductivity. What is the application fileds of PA66-LCF? 1. Military industry LFT long carbon fiber composite has very high specific strength and stiffness, and has the characteristics of corrosion resistance, fatigue resistance, high temperature resistance and low thermal expansion coefficient, etc. LCF carbon fiber composite is widely used in rocket, missile, military aircraft, personal protection and other military fields at home and abroad. Compared with conventional materials, long carbon fiber composites allow for continuous improvements in the performance of military equipment, such as reducing the weight of warships by 20 to 40 percent. At the same time, LCF carbon fiber composite material can overcome the metal material is easy to be corroded, easy to fatigue and other shortcomings, improve and enhance the durability of military products. Currently, more than 40 percent of LCF carbon fiber composite materials are used in some advanced military helicopters, and even more in unmanned aerial vehicles. In addition to aircraft, Marine warships also appear long carbon fiber composite material figure, because long carbon fiber composite material can withstand the corrosion of seawater and a variety of chemical impurities, has a long service life, more durable than steel warships, lower maintenance costs, has become an important strategic material for the development of modern defense military weapons and equipment. 2. Home appliance field LCF carbon fiber composite material has low density, good chemical resistance, excellent performance and other characteristics, has gradually become the home appliance industry's preferred modified engineering plastics, its usage accounts for about 30% and is on the rise. Moreover, home appliances are more and more intelligent and personalized, and the modified performance requirements of materials are higher. So it's no surprise that long carbon fiber composites are chosen by th...