item no.:

PA66-NA-LCF40Payment:

T/T or L/C (other payment ways also can be diproduct origin:

Xiamen, ChinaColor:

Original color (also can be customized)shipping port:

Xiamen, ChinaPA66 Material

Nylon 66 is made by the condensation of adipdiamine and adiponic acid. The common nylon is a kind of crystalline polymer. The melting point of nylon 66 reported by different brands and different test methods is between 250-271℃.

Because the phthalamine group of the amorphous part of nylon 66 is easy to combine with water molecules, the water absorption rate of nylon 66 is higher at room temperature.

Compared with general plastics, nylon 66 impact toughness, good wear resistance, friction noise is small, in addition, nylon 66 on hydrocarbon solvents, especially gasoline and lubricating oil resistance is strong.

Ninety percent of nylon 66 is used in industrial products. Among them, the consumption of nylon in the automobile industry accounts for 37% of the total consumption, its uses include oil storage tank, cylinder cover, radiator, fuel tank, water tank, water pump impeller, wheel cover, intake pipe, handle, gear, bearing, bearing bush, outer plate, terminal and so on.

The second largest application of nylon 66 is in the electronic and electrical industry, accounting for 22% of the total consumption. Its uses include electrical enclosures, plug-ins, terminals and so on. In addition, Nylon 66 is also widely used in cultural office supplies, medical and health supplies, tools, toys and other occasions.

LCF Material

PA66 has excellent mechanical properties, wear resistance, self-lubrication and corrosion resistance, and good molding processability. However, PA66 has high water absorption, poor dimensional stability and electrical properties, and its heat resistance and low temperature impact properties also need to be improved.

In order to improve the physical and mechanical properties of PA66 and expand its application range, people modified PA66 by filling enhancement, blending and other methods, and developed a series of high performance and high functional modified PA66 new varieties.

In recent years, the development speed of composite materials is very amazing, and the research of functional PA is also very active. In order to meet the requirements of use and expand its application space, the development of multifunctional PA materials has become a new research topic.

Adding fiber reinforced material to PA66 resin can not only maintain the advantages of chemical resistance and processing properties of PA66 resin, but also greatly improve the mechanical properties, heat resistance, dimensional stability and so on.

Studies show that the effect of carbon fiber on toughening nylon 66 is more significant than that of glass fiber, as shown in PA66/GF/ POE >PA66/CF>PA66/GF. This is because carbon fiber is a more rigid material than glass fiber. After composite with PA66 matrix, carbon fiber can take advantage of the high strength of carbon fiber to withstand stress. The plasticity of the matrix and its adhesion to the fiber are used to transfer stress.

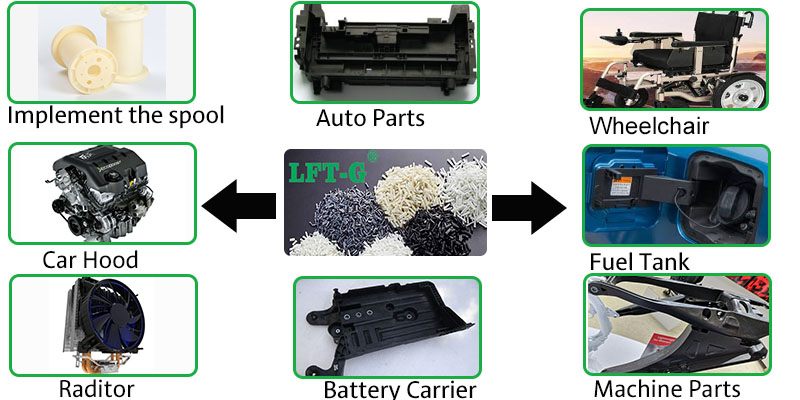

Application

Other products can contact us for advice.

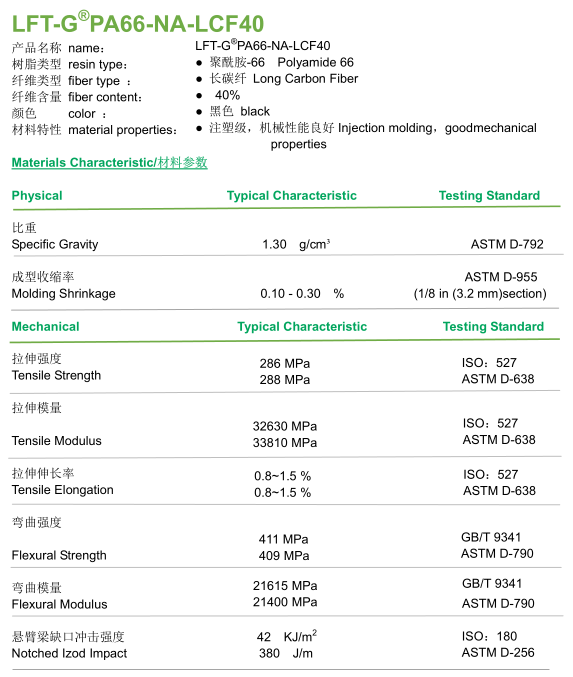

Datasheet for reference

About us

Xiamen LFT composite plastic Co., Ltd. is a brand-name company that focuses on LFT & LFRT. Long Glass Fiber Series(LGF) & Long Carbon Fiber Series(LCF). The company's thermoplastic LFT can be used for LFT-G injection molding and extrusion, and can also be used for LFT-D molding. It can be produced according to customer requirements: 5~25mm length.The company's long-fiber continuous infiltration reinforced thermoplatics have passed ISO9001%16949 system certification, and the products have obtained lots of national trademarks and patents.