item no.:

PP-NA-LCFPayment:

T/T or L/C (other payment ways also can be diproduct origin:

Xiamen, ChinaColor:

Original color (also can be customized)shipping port:

Xiamen, ChinaLead Time:

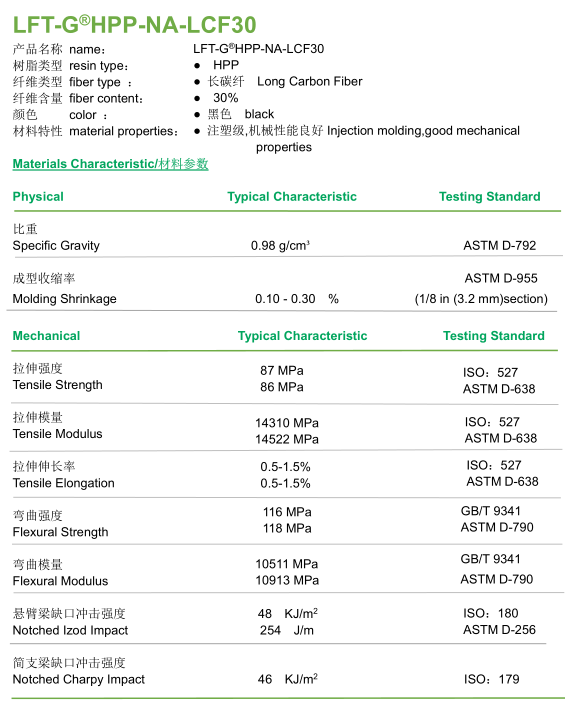

7-15 days after shipmentPolypropylene (PP) is a cost-effective polymer with excellent overall performance and wide application. When reinforced with carbon fiber, PP exhibits significantly improved mechanical strength, heat deflection temperature, and dimensional stability, greatly expanding its application range.

PP long carbon fiber composites are widely used in electronics and electrical appliances, automotive components, construction, and other industrial fields. Especially in the automotive industry, driven by the rapid development of new energy vehicles and lightweight design trends, carbon fiber reinforced PP materials are gaining increasing adoption.

Carbon fiber reinforced polypropylene offers advantages such as lightweight structure, high modulus, high specific strength, low thermal expansion coefficient, excellent heat resistance, thermal shock resistance, corrosion resistance, and vibration damping performance.

These properties make PP-LCF composites suitable for automotive instrument panel assemblies and various structural and functional automotive components.

Car Tool Kit

Automotive Front-End Components

For additional application cases and technical consultation, please feel free to contact us.

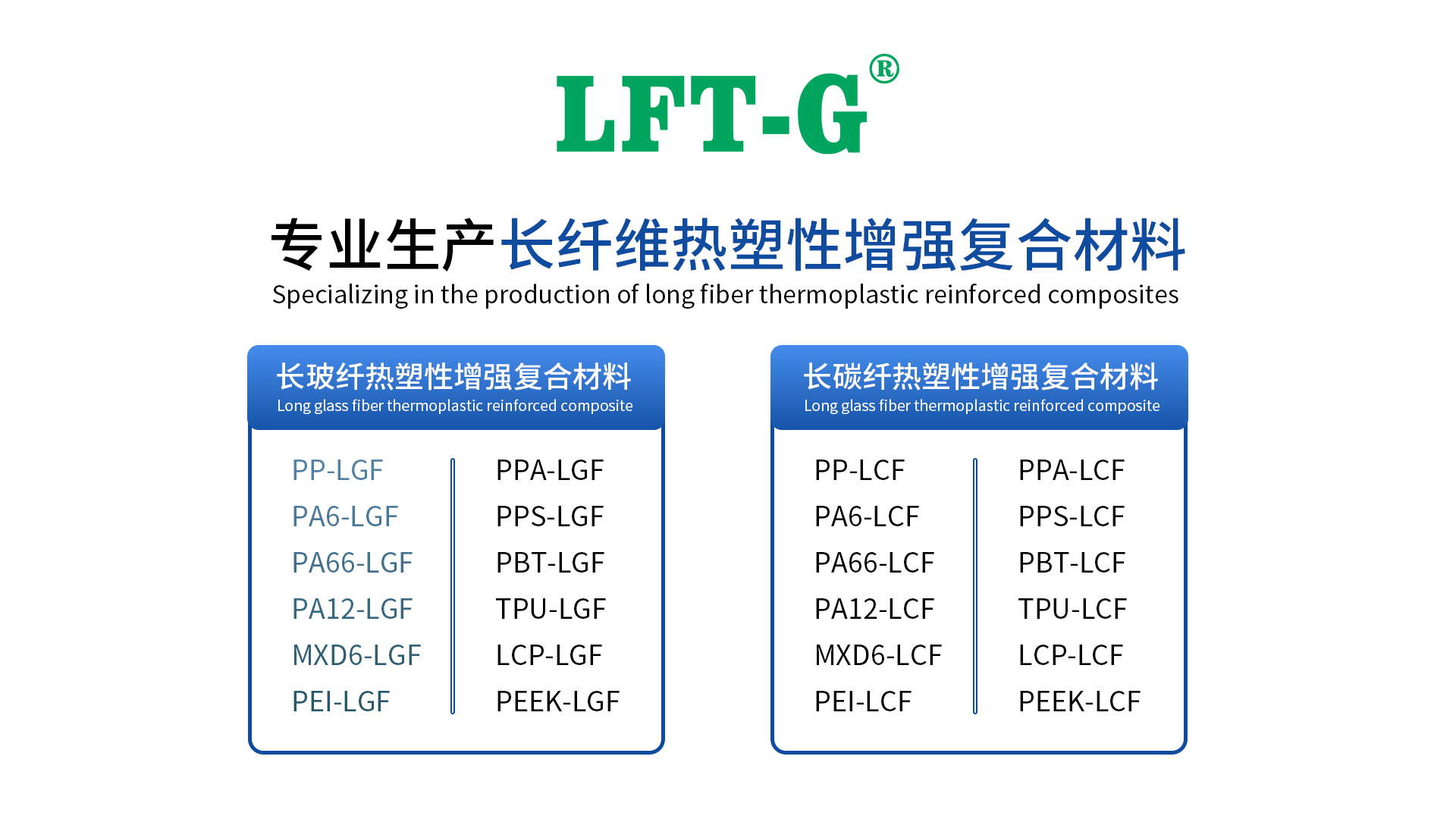

Thermoplastic carbon fiber composites use carbon fiber as reinforcement and thermoplastic resin as the matrix material. Based on fiber length, they can be classified into:

The distinction between long and short carbon fiber is generally based on application length, typically ranging from several millimeters to several centimeters, with common specifications including 6 mm, 12 mm, 20 mm, 30 mm, and 50 mm.

Thermoplastic carbon fiber composites can also be classified by resin type. While common resins include PE, PP, and PVC, high-performance applications often use advanced thermoplastics such as PEEK, PPS, PI, and PEI to achieve optimal material performance.

Thermoplastic carbon fiber composites offer excellent processability, including injection molding, compression molding, thermoforming, stamping, and bending. Once reheated to the appropriate temperature, these materials can be remolded, making them recyclable and environmentally friendly.

For example, recycled thermoplastic carbon fiber scrap can be shredded, reprocessed through injection molding, and reused for secondary products, effectively reducing material waste and overall production costs.

Compared with thermoset composites, thermoplastic carbon fiber composites feature shorter molding cycles, significantly improving production efficiency and reducing manufacturing costs.

Injection molding offers high automation, stable product quality, excellent surface appearance, and superior dimensional precision. It is particularly suitable for complex geometries and large-scale production, and is widely adopted by leading carbon fiber manufacturers.

Compression molding, on the other hand, requires simpler equipment and lower mold costs. It can be used for both thermoplastic and thermosetting composites, with minimal material loss, making it suitable for cost-sensitive mass production.