item no.:

PA66-NA-LGF40Payment:

T/T or L/C (other payment ways also can be diproduct origin:

Xiamen, ChinaColor:

Original color (also can be customized)shipping port:

Xiamen, ChinaPA66 filling LGF

Nylon (PA) has a series of excellent properties, such as high mechanical strength, chemical resistance, oil resistance, wear resistance, self-lubrication, easy processing and forming, and has become one of the thermoplastic engineering plastics widely used at home and abroad.

But in the practical application, the performance requirements of nylon are different under different conditions or environment.

For example, electric drill and motor shell, pump impeller, bearing, diesel engine and air conditioning fan and other parts require nylon material to have high strength, high rigidity and high dimensional stability; Because of the poor toughness of nylon at low temperature, it is necessary to toughen it. In some outdoor applications, nylon materials must be weather-resistant modification in long-term outdoor environment.

The reinforced materials used for nylon are mainly glass fiber, carbon fiber, whiskers and other fibrous materials, and the glass fiber reinforced is the most widely used. The glass fiber reinforcement can obviously improve the rigidity strength and hardness of the material, and the dimensional stability and heat resistance of the material are obviously improved.

Because nylon itself is not strong enough, by adding 10 to 30 percent of the fiber, to increase its strength. In particular, 30% strength is considered the most appropriate ratio. Also added to 40-50%, according to the specific requirements of different products, coupled with the appropriate formula, can be successful.

Production technology of glass fiber reinforced nylon

Long fiber method, that is, nylon and other components are premixed and added to the hopper, and the glass fiber from the glass fiber entrance through the screw rotation into the screw, and then mixed with nylon resin.

Factors affecting the properties of glass fiber reinforced nylon

Firstly, the interface bond between glass fiber and nylon resin has the most important effect on glass fiber reinforced nylon. If the combination between the two is not good, the reinforcement effect will be greatly reduced. At this time, the surface treatment of glass fiber is particularly important. Today, fiberglass manufacturers have been able to produce fiberglass models for different materials with different surface treatments for use by modified plastics manufacturers, as long as the right choice.

Second, the length of glass fiber in nylon material is another major factor affecting its properties. In general, long glass fibers are superior to short glass fibers in terms of tensile strength, bending strength and modulus, and notched impact strength.

At the same time, the dispersion of glass fiber in the material can not be ignored. The dispersion of glass fiber mainly depends on the appropriate shearing action of twin-screw and the kneading action of material, which involves the combination and speed of screw. The selection of screw speed is related to the content of additives such as glass fiber in the formula. For flame-retardant reinforced nylon, low speed is appropriate because the flame retardant has been decomposed by heat.

In addition, processing temperature, glass fiber diameter, glass fiber type will also affect the final performance of the material, so it will not be repeated here.

Glass fiber enhances the fluidity of nylon

The fluidity of glass fiber reinforced nylon is poor, and problems such as high injection pressure, high injection temperature, dissatisfaction with injection molding and poor surface quality are easy to occur in the process of injection molding, which seriously affect the appearance of products and lead to a high defect rate of products. Especially in the production process of injection molding products, and can not directly add lubricant to solve the problem, can only be improved on the raw material, generally speaking, this needs to be added in the modified formula lubrication componentS.

Resistance of glass fiber reinforced nylon to high temperature heat and oxygen aging

In some applications such as bearings and diesel fans, glass fiber reinforced nylon often faces the problem of long time high temperature thermal and oxygen aging. Although the reinforced modification of nylon with glass fiber can moderately improve the heat resistance of nylon, it can not solve the problem well. Better results can be achieved by adding appropriate anti-thermal oxygen aging additives to the glass fiber reinforced nylon composite material, as shown in the figure above.

Glass fiber enhances the weather resistance of nylon

Nylon under the influence of sunlight, temperature change, wind and rain and other external conditions, there will be a series of aging phenomena such as fading, discoloration, cracking, powder and strength reduction, among which UV is the key factor to promote aging. Weather resistant nylon is currently mainly black products, that is, by adding carbon black and other ultraviolet absorption additives in nylon to solve its weather resistance. But in addition to black products, natural or light colored nylon in outdoor application also often face the problem of aging, mainly manifested as yellow parts.

Application of nylon with different fiber ratio

Glass fiber with a proportion of 40-50% reinforced nylon material, mainly suitable for high strength gear, professional equipment of high strength parts manufacturing.

Glass fiber with a proportion of 25-35% reinforced nylon material, mainly suitable for auto parts, electric tool shell, electrical blades, wind wheels, tableware, toys and other medium strength parts manufacturing.

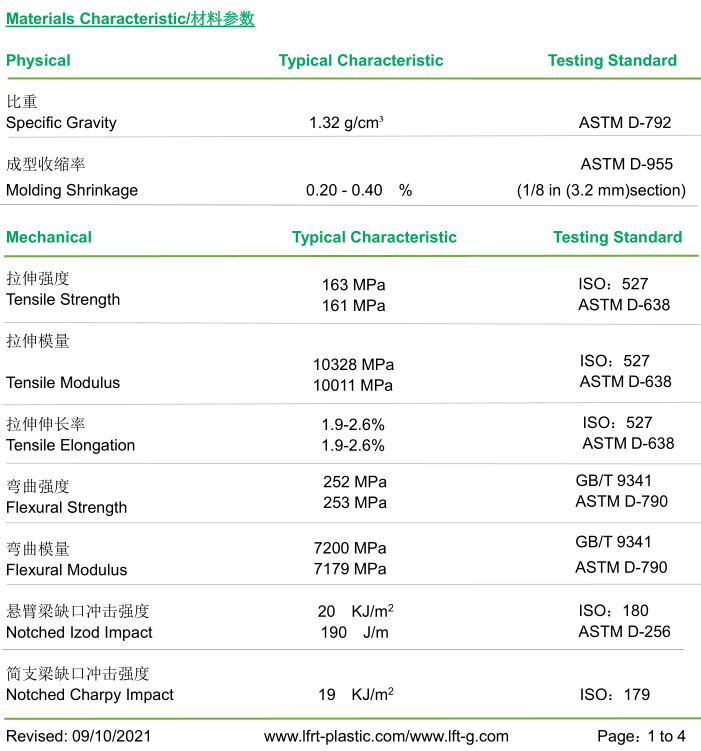

Datasheet

Tested by our own lab, for reference only.

Details