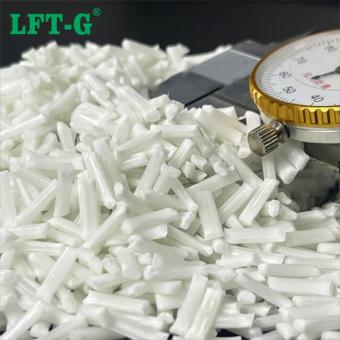

Homopolymer Long Glass fiber Reinforced Polypropylene PP;Polypropylene homopolymer long glass fiber is polymerized from a single propylene monomer, with high crystallinity, good mechanical strength and heat resistance.

-

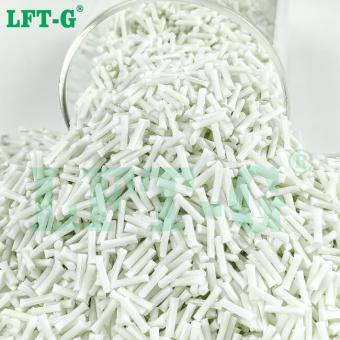

LFT High perofrmance Polypropylene with fiber LFT materials injection molding compoundPP glass fiber compound is a combination of PP resin, glass fiber and other specific additives PP glass fiber compound is made of PP base resin, glass fiber, and other additives. It gives the final products increased flexural modulus and tensile strength. With those high-performance properties, glass fiber-reinforced polypropylene delivers superior strength for furniture, electric appliances, and automobile applications.

- pp resin filament plastic metal replacement

- directly processed high tensile strength

- Improve stiffness reduce shrinkage

- Enhance impact strength and thermal resistance

- ISO FDA Certificate ROHS REACH

- car parts washing machine drum parts

Tags :

-

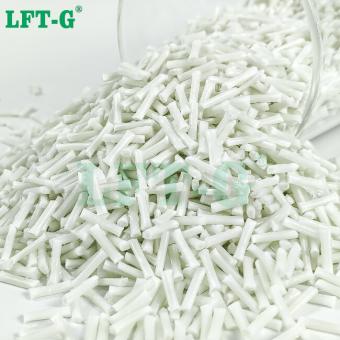

HPP genergal grade filling Long Glass Fiber LGF Polypropylene modfied plastic reinforced materialsPolypropylene, also known as PP, is a polyolefin or saturated polymer. It is a low-density thermoplastic with good resistance to heat. Other characteristics of PP include: chemical resistance, elasticity, toughness, fatigue resistance, and electrical insulation capability.

- PP GF30

- metal replacement solutions

- lft materials

- glass fiber filled pp

- pp injection molding

- pp pellets

Tags :

-

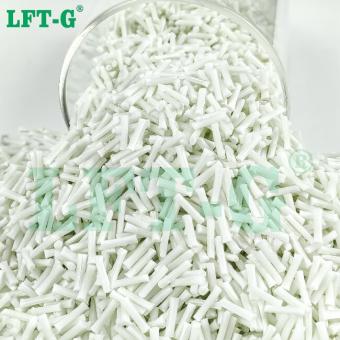

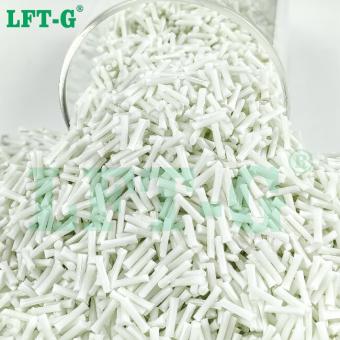

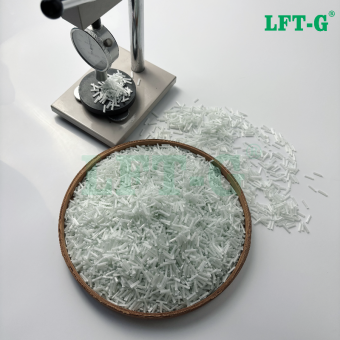

PP Pellets Glass FiberIn the manufacturing industry, in order to match some output products that require higher quality than usual, manufacturers will mix into PP plastic with glass fiber. These two different forms of glass enhancement are inherently tough and durable, so when mixed, glass-filled polypropylene materials become lighter and stronger.

- pp polypropylene

- polypropylene polymer

- polypropylene with glass fiber

- polypropylene polymer structure

- polypropylene homo polymer

- gfrp

Tags :

-

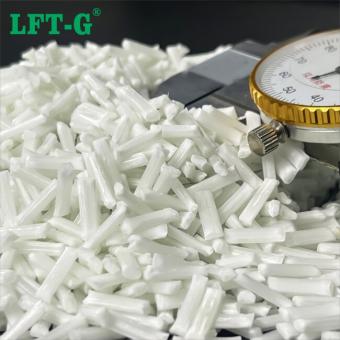

PP Composite Pellets with 20-60% Long Glass Fiber ContentLong glass fiber reinforced PP offers excellent impact resistance, lightweight strength, and dimensional stability, making it ideal for structural and automotive parts. The integration of long glass fibers greatly improves mechanical performance compared to standard polypropylene.

- pp fiber

- glass filled pp

- fiber glass companies

- fiber glass manufacturer

- glass fiber prepreg

- fiber glass density

Tags :

-

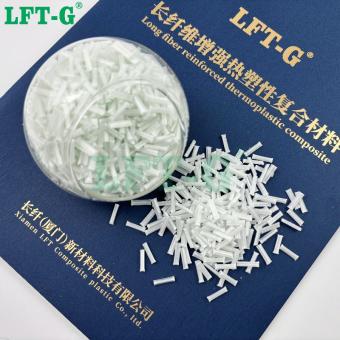

Long Glass Fiber Reinforced Composites PP SeriesThe modified polypropylene material reinforced by glass fiber has a series of advantages, such as light weight, high modulus, high specific strength, low coefficient of thermal expansion, high temperature resistance, heat shock resistance, corrosion resistance, good vibration absorption, etc., and can be applied to auto parts such as automobile sub-instrument assembly.view more

-

High Performance PP Long Glass Fiber Polymer PelletsPolypropylene, also known as PP or polypropene, is a polyolefin or saturated polymer. It is a low-density thermoplastic with good resistance to heat. Other characteristics of PP include: chemical resistance, elasticity, toughness, fatigue resistance, and electrical insulation capability.

- homopolymer example

- copolymer vs homopolymer polypropylene

- pp gf40

- PP for injection molding

- fiberglass pp

- plastic factory

Tags :

-

Xiamen LFT-G Homopolymer Polypropylene reinforced Long Glass Fiber compondsHPP is Homopolymer polypropylene. These processes produce homopolymers for several industries including: automotive, packing, medical, consumer goods, and food containers. Within these industries, the homopolymers' corrosion resistance makes them ideal for containers, tanks, and pipes. Its dimensional stability allows it to be used for gears and bearings.view more

-

Glass Fiber Reinforced PP Pellets High StrengthPolypropylene, also known as PP or polypropene, is a polyolefin or saturated polymer. It is a low-density thermoplastic with good resistance to heat. Other characteristics of PP include: chemical resistance, elasticity, toughness, fatigue resistance, and electrical insulation capability.

- long glass fiber reinforced polypropylene

- wind turbine composite materials

- pp-lgf30

- oem polypropylene fiber

- long fiber thermoplastic

- fiber forms

Tags :

-

High Strength PP Long Glass Fiber Material Natural Black Custom ColorPP long glass fiber reinforced composite is a high-performance thermoplastic material made by compounding polypropylene (PP) with continuous long glass fibers. This material offers a significant improvement in mechanical properties compared to standard PP.

- polypropylene pp

- glass fiber reinforced composites

- pp polypropylene properties

- glass fiber reinforced polymer composites

- pp glass manufacturer

Tags :

-

PP Composite Pellets with 20-60% Long Glass Fiber ContentLong glass fiber reinforced PP offers excellent impact resistance, lightweight strength, and dimensional stability, making it ideal for structural and automotive parts. The integration of long glass fibers greatly improves mechanical performance compared to standard polypropylene.view more

-

China Carbon Fiber PP Polypropylene Modified CompoundsPolypropylene, also known as PP or polypropene, is a polyolefin or saturated polymer. It is a low-density thermoplastic with good resistance to heat. Other characteristics of PP include: chemical resistance, elasticity, toughness, fatigue resistance, and electrical insulation capability.

- PP Glass fiber

- PP composites

- pp resin

- polypropylene reinforced plastics

- pp for chairs

- glassfiber pp

Tags :

-

Homo Polypropylene Glass Fiber Polymer Wide ApplicationsPolypropylene, also known as PP or polypropene, is a polyolefin or saturated polymer. It is a low-density thermoplastic with good resistance to heat. Other characteristics of PP include: chemical resistance, elasticity, toughness, fatigue resistance, and electrical insulation capability.

- fiber glass resins

- gfrc glass fiber reinforced concrete

- properties of fiber glass

- what is homopolymer and copolymer

- China PP supplier

Tags :

e-mail

e-mail English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português العربية

العربية 日本語

日本語 한국의

한국의 中文

中文