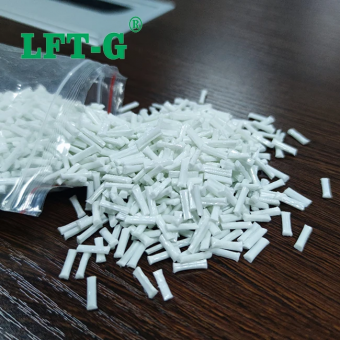

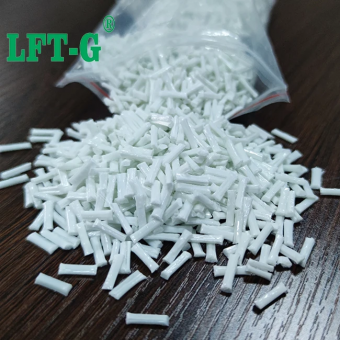

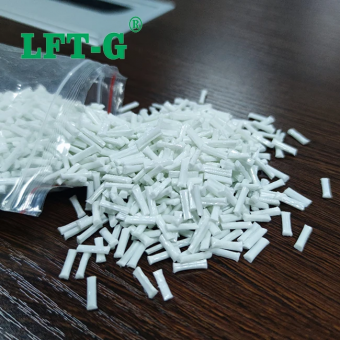

PBT plastic material modification. Long Glass fiber Reinforced Poly (butylene terephthalate) PBT High toughness High impact Non-deformation Applied to electronic and electrical products High insulation production

-

Excellent Regidity PBT Long Glass Fiber Plastic Injection MoldingAdding glass fiber to PBT is a commonly used method to enhance and modify PBT. The bonding force between glass fiber and PBT resin is good. After adding a certain amount of glass fiber to PBT resin, it can not only maintain the original advantages of PBT resin such as chemical resistance and processability, but also greatly improve its mechanical properties and overcome the problems. PBT resin notch sensitivity.view more

-

LFT-G engineering plastic PBT filling long glass fiber 20%-60% reinforced materials high mechanical properties good pricePBT Plastic | Long Glass Fiber Reinforced PBT (PBT-LGF) What is PBT? Polybutylene terephthalate (PBT) is a semi-crystalline engineering thermoplastic polyester. It is produced via polycondensation of 1,4-butylene glycol and terephthalic acid (PTA) or dimethyl terephthalate (DMT), forming a milky white translucent to opaque resin. PBT exhibits excellent mechanical strength, chemical resistance, thermal stability, and electrical insulation properties, making it ideal for demanding engineering applications. Basic Properties of PBT Specific gravity: 1.31 g/cm³ Melting point: 225~275°C Glass transition temperature (Tg): 22–43°C Rockwell hardness (R scale): 118 Water absorption: 0.34% Molding shrinkage: 1.7~2.3% PBT-LGF | Long Glass Fiber Reinforced PBT PBT-LGF combines PBT with long glass fibers, improving mechanical strength, fatigue resistance, dimensional stability, and creep resistance. These properties are maintained even under high-temperature conditions. Advantages of PBT-LGF Excellent mechanical strength and fatigue resistance High heat resistance: UL temperature index 120–140°C Good solvent resistance and no stress cracking Easy flame-retardant processing: UL94 V-0 achievable Excellent electrical insulation: high resistivity, dielectric strength, arc resistance Good molding and secondary processing: injection molding and extrusion Fast crystallization and good fluidity: thin walls can be processed in seconds PBT-LGF Technical Data Sheet (TDS) Applications of PBT-LGF Long glass fiber reinforced PBT is widely used in electronics, automotive, and industrial applications due to its high mechanical strength, heat resistance, electrical insulation, and dimensional stability. Electronics: fuse-less wire breakers, electromagnetic switches, transformers, appliance handles, connectors, housings Automotive: door handles, bumpers, distributor covers, fenders, wire guard shells, wheel covers Industrial parts: OA fans, keyboards, fishing reels, lampshades, and other mechanical components Processing of PBT-LGF PBT-LGF can be easily processed via injection molding or extrusion using standard equipment. Due to fast crystallization and good fluidity, mold temperatures are lower than other engineering plastics, enabling rapid processing of both thin-walled and large parts. PBT-LGF Product Details Number Color Length Sample MOQ Package Port of Loading Delivery time PBT-NA-LGF30 Natural color (customizable) 12mm (customizable) Available 1 ton 25kg/bag Xiamen Port 7-15 days after shipment Lab & Factory Frequently Asked Questions Q: Does long glass fiber injection require special molding machines or molds? A: Yes. Injection molding machines, screws, nozzles, and mold structures must meet long fiber reinforcement requirements. Q: How to prevent rough surfaces or floating fibers in PBT-LGF injection molding? A: Ensure plastic particles are fully dried and plasticized, adjust mold temperature appropriately, and polish mold surfaces for smooth finishes.

- PBT pellets lgf 30 polymer

- LFT PBT modified plastic glass fiber

- reinforced PBT for car parts gfrp

- self owing pbt pellets

- best price PBT glass fiber compounds

- composite pbt-lgf sample free

Tags :

-

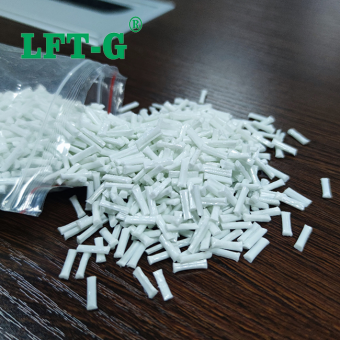

PBT Pellets Glass FiberPBT GF30 is a high-performance thermoplastic composite material that offers exceptional mechanical strength and heat resistance. This composite material is created by reinforcing polybutylene terephthalate (PBT) resin with 30% glass fibers. PBT GF30 finds its applications in various industries due to its unique properties and benefits.

- reinforced glass fiber

- polybutylene terephthalate resin

- glass fiber reinforced polymers

- glass fiber reinforced polymer composites

- pbt fiber

Tags :

-

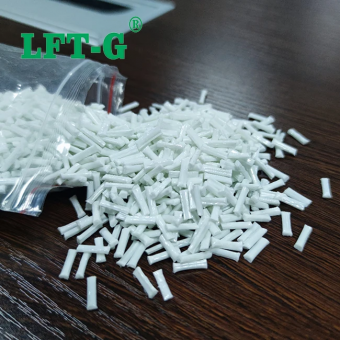

High Strength PBT Composite for Advanced Structural ApplicationsOur PBT Long Glass Fiber Reinforced Structural Composite Material combines high-performance Polybutylene Terephthalate (PBT) resin with long glass fiber (LGF) to create a material that delivers exceptional strength, heat resistance, and dimensional stability. This advanced material is designed for demanding applications in industries such as automotive, electronics, and industrial machinery.

- lft plastic

- lft container color

- pbt fiber compounds

- polymer price per kg

- wholesale glass fiber reinforced plastic resin dispenser in china

Tags :

-

Long Glass Fiber Reinforced Composites PBT SeriesPBT has properties similar to those of PET (polyethylene terephthalate). It is known for its dimensional stability, low moisture absorption, high strength, stiffness, and chemical, UV, and thermal resistance. It is commonly used in automotive fenders and interior trim pieces, power tool housings, and electrical enclosures.

- LFT-G

- High-performance PBT composite

- Injection molding PBT resin

- High-strength industrial plastic parts

- Flame-retardant PBT composite

- Structural plastic replacement for metal

Tags :

-

High Dimensional Stability PBT Long Glass Fiber Polymer PelletsPBT has properties similar to those of PET (polyethylene terephthalate). It is known for its dimensional stability, low moisture absorption, high strength, stiffness, and chemical, UV, and thermal resistance. It is commonly used in automotive fenders and interior trim pieces, power tool housings, and electrical enclosures.

- pbt material

- glassfiber gf reinforced pbt market

- pbt resin

- pbt plastic

- glass filled pbt

- pbt-gf10

Tags :

-

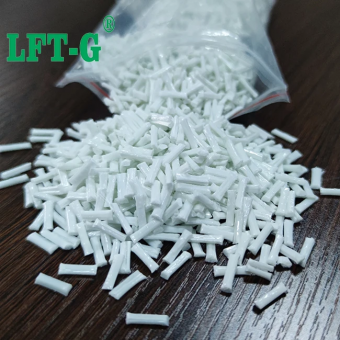

Glass Fiber Reinforced PBT Resin Pellets Injection MoldingAdding glass fiber to PBT is a commonly used method to enhance and modify PBT. The bonding force between glass fiber and PBT resin is good. After adding a certain amount of glass fiber to PBT resin, it can not only maintain the original advantages of PBT resin such as chemical resistance and processability, but also greatly improve its mechanical properties and overcome the problems. PBT resin notch sensitivity.

- pbt gf40

Tags :

-

Excellent Regidity PBT Long Glass Fiber Plastic Injection MoldingAdding glass fiber to PBT is a commonly used method to enhance and modify PBT. The bonding force between glass fiber and PBT resin is good. After adding a certain amount of glass fiber to PBT resin, it can not only maintain the original advantages of PBT resin such as chemical resistance and processability, but also greatly improve its mechanical properties and overcome the problems. PBT resin notch sensitivity.view more

-

PBT Composite Pellets with 20-60% Long Glass Fiber ContentPBT Long Glass Fiber Reinforced Material offers excellent dimensional stability, high strength, and outstanding chemical resistance. It is ideal for structural components requiring durability, heat resistance, and long-term mechanical performance.

- plastic resin manufacturer

- glass fiber reinforced plastic

- engineering plastic

- long glass fiber

Tags :

-

LFT PBT Polybutylene terephthalate Long Glass Fiber filled CompositesOne of the remarkable features of PBT-GF is its excellent dimensional stability. The presence of glass fibers greatly reduces the material's tendency to expand or contract under varying temperature conditions. This property ensures that PBT GF retains its shape and size, making it suitable for applications that demand tight tolerances and precise dimensions.view more

-

High Tensile Strength PBT Glass Fiber Polymer Wide ApplicationsPBT has properties similar to those of PET (polyethylene terephthalate). It is known for its dimensional stability, low moisture absorption, high strength, stiffness, and chemical, UV, and thermal resistance. It is commonly used in automotive fenders and interior trim pieces, power tool housings, and electrical enclosures.

- what is PBT plastic

- density glass fiber

- flow marks in injection molding

- PBT GF

- Electronic & electrical PBT enclosures

- China pbt resin

Tags :

-

PBT Plastic Reinforced Compounds Long Fiber FilledPolyphthalamide is a high-performance resin and member of the nylon family with exceptional thermal, mechanical, and physical properties. It is hygroscopic, opaque, semicrystalline, and can be used in plastic injection molding. Most PPA are filled with glass fiber or carbon fiber to enhance stiffness for high-temperature applications. As a result, PPA is often used in applications in place of metal or higher-priced thermoplastic.

- PBT composite material

- lightweight PBT plastic for drones

- PBT GF30 vs GF50 comparison

- PBT engineering plastic

- glass fiber PBT for battery housings

- heat resistant PBT thermoplastics

Tags :

e-mail

e-mail English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português العربية

العربية 日本語

日本語 한국의

한국의 中文

中文