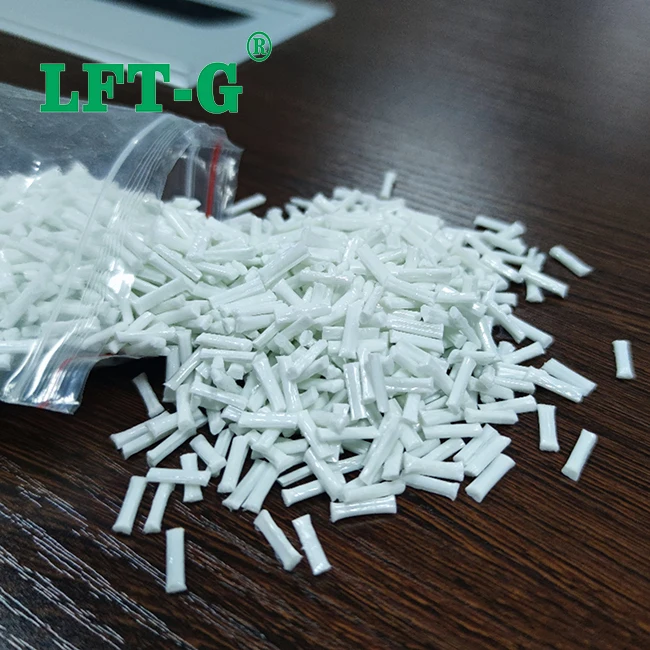

item no.:

PBT-NA-LGFPayment:

Discussedproduct origin:

ChinaColor:

Natural color or Customizedshipping port:

XiamenLead Time:

2-10 working days

When PBT is combined with glass fiber, it will produce the following effects:

1. Enhance strength and stiffness: Glass fiber has excellent strength and stiffness, and adding it to PBT can significantly increase the mechanical properties of plastics. This makes the PBT plus glass fiber material stronger and more rigid when bearing force or stress, and is less likely to deform or break.

2. Improve heat resistance: Glass fiber has a higher melting point and has good heat resistance. When glass fiber is added to PBT, it can improve the heat resistance of PBT, allowing it to maintain better performance at higher temperatures and prevent softening or melting.

3. Improve corrosion resistance: Glass fiber has excellent corrosion resistance, and adding it to PBT can improve its resistance to chemicals, solvents and other corrosive media. This allows the PBT plus glass fiber material to have a longer service life in some special environments.

4. Improve insulation performance: PBT itself has good insulation performance, and the addition of glass fiber further improves the insulation performance of PBT material. This makes PBT plus glass fiber materials more suitable for electrical and electronic applications, which can effectively isolate current and reduce leakage and electromagnetic interference.

25kg moisture-resistant bags

Note: Values vary based on customized formulations. Full TDS provided upon request.

| Property | Value |

|---|---|

| Density | ~1.53 g/cm³ |

| Tensile Strength | 142 MPa |

| Flexural Modulus | 9548 GPa |

| HDT | 200 °C |

| Carbon Fiber Content | 30% |

Full TDS and test curves will be provided after formulation confirmation.

Structural & functional components such as luggage frames, chassis supports, and interior structural parts.

Housings, support structures, and functional load-bearing parts.

Internal frames, casings, and load-bearing components.

Frames, trusses, and other high stiffness-to-weight elements.

Xiamen LFT Composite Plastics Co., Ltd.

Global Leading Supplier of Long Fiber Reinforced Thermoplastics

Email: sale02@lfrtplastic.com · Website: www.lft-g.com · Address: No.55 Hongxi South Road, Torch High-tech Zone (Xiangan) Industrial Park. Xiamen 361000 · Phone: +86-13950095727

© Xiamen LFT Composite Plastics Co., Ltd.

All rights reserved.