item no.:

PBT-NA-LGF30Payment:

T/T or L/C (other payment ways also can be diproduct origin:

Xiamen, ChinaColor:

Original color (also can be customized)shipping port:

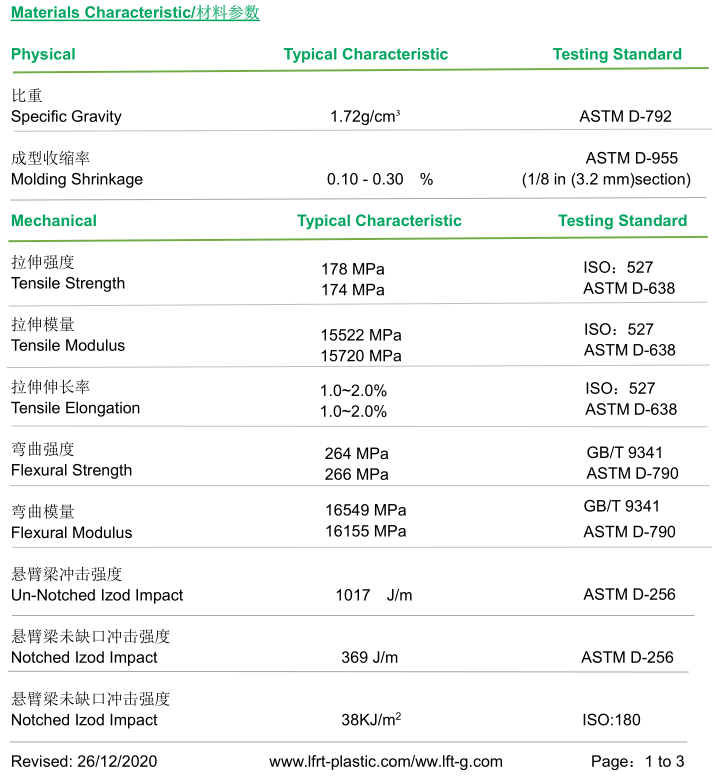

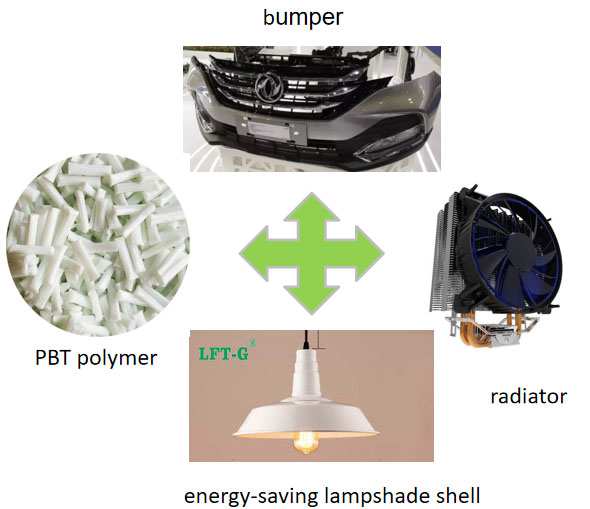

Xiamen, ChinaPolybutylene terephthalate (PBT) is a semi-crystalline engineering thermoplastic polyester. It is produced via polycondensation of 1,4-butylene glycol and terephthalic acid (PTA) or dimethyl terephthalate (DMT), forming a milky white translucent to opaque resin. PBT exhibits excellent mechanical strength, chemical resistance, thermal stability, and electrical insulation properties, making it ideal for demanding engineering applications.

PBT-LGF combines PBT with long glass fibers, improving mechanical strength, fatigue resistance, dimensional stability, and creep resistance. These properties are maintained even under high-temperature conditions.

Long glass fiber reinforced PBT is widely used in electronics, automotive, and industrial applications due to its high mechanical strength, heat resistance, electrical insulation, and dimensional stability.

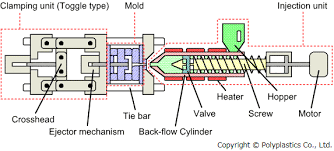

PBT-LGF can be easily processed via injection molding or extrusion using standard equipment. Due to fast crystallization and good fluidity, mold temperatures are lower than other engineering plastics, enabling rapid processing of both thin-walled and large parts.

| Number | Color | Length | Sample | MOQ | Package | Port of Loading | Delivery time |

|---|---|---|---|---|---|---|---|

| PBT-NA-LGF30 | Natural color (customizable) | 12mm (customizable) | Available | 1 ton | 25kg/bag | Xiamen Port | 7-15 days after shipment |

Q: Does long glass fiber injection require special molding machines or molds?

A: Yes. Injection molding machines, screws, nozzles, and mold structures must meet long fiber reinforcement requirements.

Q: How to prevent rough surfaces or floating fibers in PBT-LGF injection molding?

A: Ensure plastic particles are fully dried and plasticized, adjust mold temperature appropriately, and polish mold surfaces for smooth finishes.