-

Advanced Carbon Materials Nylon 6 PelletsPA6 long carbon fiber reinforced material offers high strength, excellent impact resistance, and lightweight properties. It provides outstanding dimensional stability and fatigue resistance, making it ideal for automotive and industrial applications. Suitable for replacing metal components to achieve weight reduction and enhanced performance.

- nylon pellets

- pa6 price per kg

- china plastic raw materials

- CFRP materials

- China manufacturer carbon fiber

- Polyamide 6 plastics

Tags :

-

PP CF Thermoplastic Plastics Carbon Fiber Plastic CompoundsThe modified polypropylene material reinforced by carbon fiber has a series of advantages, such as light weight, high modulus, high specific strength, low coefficient of thermal expansion, high temperature resistance, heat shock resistance, corrosion resistance, good vibration absorption, etc., and can be applied to auto parts such as automobile sub-instrument assembly.

- aramid carbon fiber

- carbon fiber thermoplastic composite

- what is a homopolymer

- oem polypropylene fiber

- homopolymers and copolymers

- polymer vs copolymer

Tags :

-

Advanced Carbon Materials Nylon 12 Resin Long Carbon Fiber Reinforced PelletsPA12 long carbon fiber reinforced material offers excellent impact resistance, low moisture absorption, and dimensional stability, making it ideal for demanding engineering applications. With superior mechanical properties and lightweight advantages, this material is widely used in automotive, electronics, and electrical industries. Its high strength and rigidity ensure stable performance even in harsh environments.

- plastic pellets for car

- pa12 pellets

- PA12 black

- pa12 carbon fiber

- PA12 polymer

- carbon fiber nylon pa12

Tags :

-

MXD6 Polyamide Composite Pellets with 20-60% Long Glass Fiber ContentMXD6 is a high-performance semi-aromatic polyamide known for its exceptional gas barrier properties, mechanical strength, and thermal stability. It is widely used in automotive, packaging, and industrial applications where durability and chemical resistance are essential. Ideal for structural and functional components, MXD6 delivers reliable performance in demanding environments.view more

-

Glass Fiber Reinforced PE High Density Resin Pellets Injection MoldingThis material combines high-density polyethylene (HDPE) with long glass fibers for enhanced mechanical strength, impact resistance, and dimensional stability. It is ideal for structural applications requiring durability, lightweight, and chemical resistance, commonly used in automotive, industrial, and outdoor products.

- fiber reinforced hdpe composite pipe

- hdpe glass

- metal replacement solutions

- thermoplastic composite materials

- lft pellets

- long fibres composites

Tags :

-

Glass Fiber Reinforced PLA Resin Pellets Injection MoldingPLA itself is an environmentally friendly thermoplastic, known for its biodegradability. However, it has limited mechanical properties, such as strength, toughness, and heat resistance. By incorporating long glass fibers, the performance of PLA is significantly improved, making it suitable for demanding applications.

- pps plastic

- long-fiber thermoplastic composite solutions

- pla plastic pellets

- thermoplastic glass fiber composite

- thermoplastic gfrp

Tags :

-

Glass Fiber Reinforced ABS Resin Pellets Injection MoldingAfter adding glass fiber to ABS, the rigidity, heat resistance and dimensional stability of the composite are significantly improved. In addition, the cost performance of ABS plus glass fiber is extremely good, which can meet the needs of manufacturers while reducing costs.

- abs plastic melting point

- abs plastic pellets

- abs granules manufacturer

- natural abs color

- abs glass fiber compound

- abs raw material

Tags :

-

Excellent Regidity PBT Long Glass Fiber Plastic Injection MoldingAdding glass fiber to PBT is a commonly used method to enhance and modify PBT. The bonding force between glass fiber and PBT resin is good. After adding a certain amount of glass fiber to PBT resin, it can not only maintain the original advantages of PBT resin such as chemical resistance and processability, but also greatly improve its mechanical properties and overcome the problems. PBT resin notch sensitivity.view more

-

Glass Fiber Reinforced PLA Resin Pellets Injection MoldingPLA itself is an environmentally friendly thermoplastic, known for its biodegradability. However, it has limited mechanical properties, such as strength, toughness, and heat resistance. By incorporating long glass fibers, the performance of PLA is significantly improved, making it suitable for demanding applications.view more

-

LFT-G PPS Polyphenylene sulfide LGF composite long glass fiber customized engineering plasticsPPS & PPS-LGF | High Performance Engineering Plastic body { font-family: Arial, Helvetica, sans-serif; line-height: 1.6; color: #333; } h2 { font-size: 24px; margin-top: 40px; } h3 { font-size: 20px; margin-top: 25px; } p { font-size: 16px; margin: 12px 0; } ul { font-size: 16px; margin-left: 20px; } table { width: 100%; border-collapse: collapse; margin-top: 20px; } table, th, td { border: 1px solid #000; } th, td { padding: 10px; text-align: center; font-size: 16px; } img { max-width: 100%; margin: 20px 0; } What Is PPS? Polyphenylene Sulfide (PPS) is a high-performance engineering thermoplastic known for its excellent heat resistance, chemical stability, flame retardancy, and mechanical strength. Through reinforcement and modification, PPS offers a well-balanced combination of physical, mechanical, and electrical properties. PPS features outstanding dimensional stability, corrosion resistance, and electrical insulation performance, making it suitable for harsh industrial environments. Key Characteristics of PPS Excellent high-temperature resistance High hardness and wear resistance Strong creep resistance under long-term load Excellent electrical properties over a wide temperature range Low sensitivity of mechanical properties to temperature changes Unmodified PPS is naturally brittle and has relatively low impact strength. These limitations can be effectively overcome through fiber reinforcement and material modification. What Is PPS-LGF? PPS-LGF refers to Polyphenylene Sulfide reinforced with Long Glass Fiber. Among engineering plastics, PPS-LGF stands out for its superior heat resistance, structural strength, and long-term reliability. Heat deflection temperature (HDT) above 260°C Chemical resistance second only to PTFE Low molding shrinkage and extremely low water absorption Excellent flame retardancy and vibration fatigue resistance Outstanding electrical insulation even in high humidity and high-temperature environments By incorporating long glass fibers, PPS-LGF significantly improves toughness and impact strength, overcoming the brittleness of pure PPS and delivering excellent comprehensive performance. In many applications, PPS-LGF can replace metals such as stainless steel, copper, aluminum, and alloys—making it an ideal material for metal replacement and lightweight design. Applications of PPS-LGF PPS-LGF is widely used in industries requiring high strength, heat resistance, and chemical stability, including: Automotive components Aerospace structures Household appliances Mechanical and structural parts Chemical processing equipment Electrical insulation and corrosion-resistant components Product Details Grade Color Pellet Length MOQ Packaging Sample Delivery Time Port of Loading PPS-NA-LGF30 Natural (Customizable) ≥ 5–25 mm 25 kg 25 kg / bag Available 7–15 days after shipment Xiamen Port Production Process Our PPS-LGF materials are produced using advanced long-fiber impregnation technology, ensuring excellent fiber length retention, uniform dispersion, and stable mechanical performance. Trademarks and Patents Our materials are supported by proprietary technologies, registered trademarks, and patented processes to ensure consistent quality and reliable performance. Teams and Customers Backed by an experienced R&D and production team, our PPS-LGF materials are trusted by customers worldwide across automotive, industrial, and electrical sectors. What We Offer LFT & LFRT material technical data and advanced design support Mold-front design recommendations and optimization Professional technical support for injection molding and extrusion processing

- PPS Long glass fiber 40

- pps compounds lgf

- pps resin materials lft

- lft-g pps reinforced plastic

- long glass fiber filling pps

- termoplastic resin pps lgf

Tags :

-

Xiamen LFT ABS (Acrylonitrile Butadiene Styrene) Long Glass Fiber Reinforced Thermoplastic CompoundsABS-LGF (Glass Fiber Reinforced ABS) Overview ABS is a versatile engineering plastic known for chemical and thermal stability, strength, toughness, and glossy finish. It is widely used in consumer products such as toys and helmets, as well as automotive applications like interior trim, housings for electronics, and more. Reinforcing ABS with glass fiber significantly improves rigidity, heat resistance, and dimensional stability. ABS-LGF composites provide excellent cost-performance balance, helping manufacturers reduce costs while meeting production needs. About ABS-LGF Compounds Applications of Modified ABS 1. Automotive Parts: Instrument panels, fenders, interiors, lights, mirrors, audio systems. 2. Electronic & Electrical Components: IT and OA equipment shells, converters, power sockets. 3. Electronic Appliances: Switches, controllers, monitors, housings, brackets. 4. Home Appliances: Electrical components, control boxes. Advantages of ABS Injection Molding High Productivity: Efficient, low-waste process ideal for high-volume manufacturing. Complex Part Design: Capable of multi-featured components, including overmolding and metal inserts. Increased Strength: ABS provides excellent mechanical strength and durability. Flexible Color & Material Options: Easily colored, painted, or electroplated to improve environmental resistance. Decreased Waste: Low-wastage production, limited to sprue, runners, and flashing. Low Labor Cost: Highly automated process reduces human intervention and lowers cost per part. Material Details Number ABS-NA-LGF Color Natural or Customized Length 6-25 mm Package 25kg/bag MOQ 25kg Lead Time 2-15 days Port of Loading Xiamen Port Trade Terms EXW / FOB / CFR / CIF / DDU / DDP About Xiamen LFT Founded in 2009, Xiamen LFT Composite Plastics Co., Ltd. is a leading global supplier of long fiber reinforced thermoplastic materials, integrating R&D, production, and marketing. Our products are ISO9001 & IATF16949 certified, patented, and applied in automotive, aerospace, medical, new energy, military, sports equipment, and more. Compared to short fiber thermoplastics (1-2 mm fibers), our LFT materials (5-25 mm fibers) are fully impregnated with resin, ensuring superior mechanical performance. Base resins include PP, PA6, PA66, PPA, PA12, MXD6, PBT, TPU, PPS, ABS, PEEK, etc. Conventional fibers include glass and carbon fibers. Finished products can be used for injection molding, extrusion, or directly replace steel and thermoset components.

- High performance thermoplastic engineering plastics

- excellent heat resistance with filler

- injection molding products light weight

- automotive parts house hold appliances

- modified plastic manufacturer can be customized

- can be recylced GFRP GF30

Tags :

-

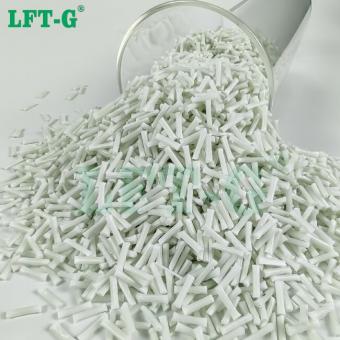

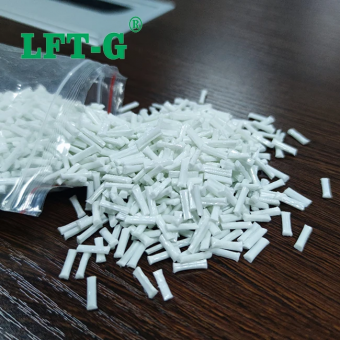

High strength PA12 nylon12 composite lgf virgin white color for automotiveProduct number: PA12-NA-LGF Fiber specification: 20%-60% Product feature: High strength, High toughness and durability Product application: Suitable for automotive, sports parts, solar energy, photovoltaic industry and other industries.

- Nylon12 filling long glass fiber reinforced plastic

- Durability high mechanical properties

- Photovoltaic industry compounds

- Injection grade thermoplastic resin

- 24h service customized plastic instead metal

- Supplier price good price pa6 composites

Tags :

e-mail

e-mail English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português العربية

العربية 日本語

日本語 한국의

한국의 中文

中文