-

PPS Engineering Plastic Resin Carbon Fiber Reinforced CompoundsPolyphenylenesulfide, is a thermoplastic special engineering plastic with excellent comprehensive properties. Its outstanding features are high temperature resistance, corrosion resistance and superior mechanical properties. The product will make a metallic sound when it is dropped to the ground.view more

-

PLA Plastic Resin with Fiber Reinforced Thermoplastic CompoundsIt takes less energy to produce PLA than petroleum-based thermoplastics, making it relatively eco-friendly. PLA is often regarded as being biodegradable.view more

-

High Tensile Strength Nylon 12 Carbon Filled Polymer PelletsA class of polymers known as engineering plastics has better mechanical and thermal characteristics than regular plastics. They are used in goods for the automotive, electrical, industrial, and domestic markets that need great performance and durability.view more

-

High Mechanical Properties Polyamide 66 PA Long Carbon Fiber Polymer PelletsNylon 6,6, also written as nylon 6-6, nylon 66, or nylon 6/6, is a more crystalline version of nylon 6. It is also referred to as polyamide 66 or PA 66. It has improved mechanical properties due to its more ordered molecular structure. Nylon 66 for machining has improved temperature resistance and lower rates of water absorption when compared to standard nylon 6.view more

-

High Mechanical Properties Nylon PA Long Carbon Fiber Polymer PelletsThe main advantages of nylon 6 are its stiffness and resistance to abrasion. Moreover, this material has excellent impact strength, wear resistance, and electrical insulating properties. Nylon 6 is a highly elastic and fatigue-resistant material, meaning it will return to its original proportions after being distorted by tension.view more

-

High Mechanical Properties PP Long Carbon Fiber Polymer PelletsPolypropylene, also known as PP or polypropene, is a polyolefin or saturated polymer. It is a low-density thermoplastic with good resistance to heat. Other characteristics of PP include: chemical resistance, elasticity, toughness, fatigue resistance, and electrical insulation capability.view more

-

High Mechanical Properties Nylon MXD6 Long Glass Fiber Polymer PelletsWith its unique balance of strength, barrier performance, and stability, MXD6-LGF is the ideal solution for demanding applications.view more

-

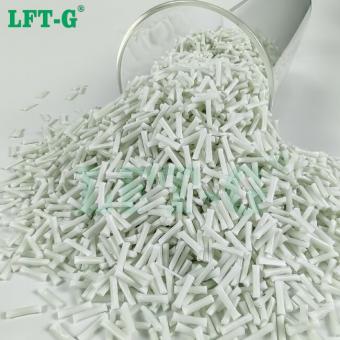

High Temperature Resistant PPS Long Glass Fiber Polymer PelletsPPS lengthened glass fiber (LGF) composite material has the advantages of high toughness, low warpage, fatigue resistance, and good product appearance. It can be used in water heater impellers, pump casings, joints, valves, chemical pump impellers and casings, cooling water impellers and Shells, home appliance parts, etc.

- PPS engineering plastic supplier

- Automotive PPS plastic parts

- PPS for industrial structural components

- long fiber thermoplastic

- PPS glass fiber reinforced material

Tags :

-

High Dimensional Stability PBT Long Glass Fiber Polymer PelletsPBT has properties similar to those of PET (polyethylene terephthalate). It is known for its dimensional stability, low moisture absorption, high strength, stiffness, and chemical, UV, and thermal resistance. It is commonly used in automotive fenders and interior trim pieces, power tool housings, and electrical enclosures.

- pbt material

- glassfiber gf reinforced pbt market

- pbt resin

- pbt plastic

- glass filled pbt

- pbt-gf10

Tags :

-

UV Resistant PE Long Glass Fiber Polymer PelletsClassified as a thermoplastic polymer in the polyethylene family, HDPE exhibits exceptional resistance to moisture, chemicals, and impact. This resilient and dense material is produced through the process of polymerization, resulting in a robust and durable substance.

- virgin pellet

- polypro pellets

- fiber reinforced hdpe composite pipe

- long fibre reinforced pellets

- lft pellets

- plastic pellets

Tags :

-

Green Materials PLA Long Glass Fiber Polymer PelletsThe addition of long glass fibers enhances the mechanical properties of PLA, such as strength, stiffness, and impact resistance. This makes LFT-PLA ideal for applications requiring high load-bearing capacity.

- reinforced thermoplastic

- reinforced pla

- modified plastic

- polylactic acid (pla) plastic

- pla pellets

- pla plastic injection molding

Tags :

-

High Imapct Resistance PPS Long Glass Fiber Polymer PelletsLFT®PPS-NA-LGF is glass reinforced PPS compound, which is filled with glass fiber based on the PPS resin.

- pps car parts

- pps plastic price

- pps pellets

- pps glass fibre

- pps plastic melting point

- pps raw material

Tags :

e-mail

e-mail English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português العربية

العربية 日本語

日本語 한국의

한국의 中文

中文