-

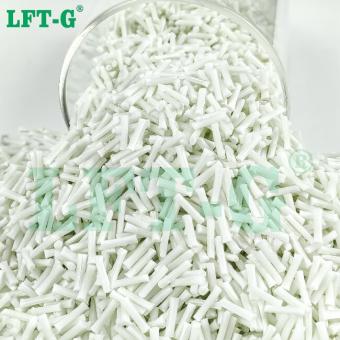

PP Pellets Glass FiberPolypropylene, also known as PP or polypropene, is a polyolefin or saturated polymer. It is a low-density thermoplastic with good resistance to heat. Other characteristics of PP include: chemical resistance, elasticity, toughness, fatigue resistance, and electrical insulation capability.

- pp polypropylene

- polypropylene polymer

- polypropylene with glass fiber

- polypropylene polymer structure

- polypropylene homo polymer

- gfrp

Tags :

-

PP Pellets Glass FiberIn the manufacturing industry, in order to match some output products that require higher quality than usual, manufacturers will mix into PP plastic with glass fiber. These two different forms of glass enhancement are inherently tough and durable, so when mixed, glass-filled polypropylene materials become lighter and stronger.view more

-

PEEK Pellets Carbon FiberPEEK can still maintain good electrical insulation in harsh environments such as high temperature, high pressure and high humidity, and has characteristics such as not easy to deform in a wide temperature range, so it is used as an ideal electrical insulation material in the field of electronic and electrical appliances.

- peek fiber

- carbon fibre peek

- carbon fiber application

- carbon fiber bicycles

- peek polymer

- carbon fiber reinforced polymer

Tags :

-

PPS Pellets Carbon FiberPPS is a high-performance, tough engineering plastic with great dimensional and thermal stability, as well as a wide operating temperature range of up to 260 °C and good chemical resistance. Moreover, PPS, like most other thermoplastics, is an electrical insulator. Its ability to be used at high temperatures coupled with its thermal stability makes PPS great for applications such as semiconductor components in machinery, bearings, and valve seats.

- polyphenylene sulfide plastic

- pps polyphenylene sulfide

- polyphenylene sulfide properties

- automotive carbon fiber

- plastic carbon fiber

- plastic pps

Tags :

-

PLA Pellets Carbon FiberLFR-PLA can be processed using conventional plastic processing techniques like injection molding and extrusion, offering good adaptability in manufacturing. It is widely used in industries like automotive, consumer electronics, 3D printing, and eco-friendly packaging due to its combination of high performance and sustainability.

- carbon fiber pla

- pla carbon fiber filament

- carbon fiber pla filament

- pla pellets

- carbon fiber automotive wheels

- pla fiber

Tags :

-

Nylon 12 Pellets Carbon FiberPolyamides are used in the automotive industry for their light weight, low cost, and good mechanical properties. Specific automotive applications include engine air intakes, car gate, engine covers, pulley tensioners, fuel lines, fuel pumps, lights, and vehicle trim.view more

-

Nylon 6 6 Reinforced Pellets PA6.6 Carbon FiberPolyamides can come in various colors including: yellow, white, and light brown. However, polyamide fibers can be dyed to any color, and solid polyamides can be surface finished with a wide variety of paint colors.

- polyamide 66

- polyamide fiber

- nylon 66 polyamide

- carbon fiber sheet molding compound

- carbon pellets

- nylon 66 is a polyamide

Tags :

-

Nylon Reinforced Pellets PA6 Carbon FiberNylon 6 is a suitable material for injection molding. The resulting molded nylon parts possess great strength, as well as chemical and temperature resistance. When molding nylon 6, the material is sometimes injected with a specified amount of glass or carbon fibers (usually between 20% and 60%) to boost its tensile strength.

- carbon fiber polishing compound

- polyamide nylon 6

- polyamide 6 density

- nylon 6 polyamide

- activated carbon pellets

Tags :

-

Homopolymer PP Carbon Reinforced Polymer Injection Molding ProductsPolypropylene, also known as PP, is a polyolefin or saturated polymer. It is a low-density thermoplastic with good resistance to heat. Other characteristics of PP include: chemical resistance, elasticity, toughness, fatigue resistance, and electrical insulation capability.

- pp homopolymer density

- fiber reinforced plastic

- fiber composite materials

- polypropylene homopolymer manufacturers

- polypropylene pellets

Tags :

-

PP CF Reinforced Polymer Injection Molding ProductsThe modified PP reinforced by carbon fiber has a series of advantages, such as light weight, high modulus, high specific strength, low coefficient of thermal expansion, high temperature resistance, heat shock resistance, corrosion resistance, good vibration absorption, etc., and can be applied to auto parts such as automobile sub-instrument assembly.

- reinforced composite materials

- carbon fiber composite materials

- fiber reinforced composite materials

- cfrp carbon fiber reinforced plastic

- carbon reinforced fiber

Tags :

-

Xiamen LFT-G Polypropylene filling long glass fiber high performance modified plastic 12mmPP-LGF Glass fiber reinforced PP, usually, the tensile strength of PP material is between 20M~30MPa, bending strength is between 25M~50MPa, bending modulus is between 800M~1500MPa. If PP is to be used in engineering structural parts, it must be reinforced with glass fiber. Glass fiber reinforced PP, through glass fiber reinforced PP product mechanical properties can be multiplied or even several times the improvement. Specifically, the tensile strength reaches 65MPa~90MPa, the bending strength reaches 70MPa~120MPa, and the bending modulus reaches 3000MPa~4500MPa. Such mechanical strength can be completely comparable with ABS and enhanced ABS products, and it is more heat resistant. Glass fiber reinforced PP, general ABS and reinforced ABS heat resistance temperature between 80℃~98℃, and glass fiber reinforced PP material heat resistance temperature can reach 135℃~145℃. PP filling modification, adding a certain amount of inorganic minerals in PP, such as talcum powder, calcium carbonate, titanium dioxide, mica, etc., can improve rigidity, improve heat resistance and luster; Filling carbon fiber, boron fiber, glass fiber can improve the tensile strength; Adding flame retardant can improve flame retardant property. Filling antistatic agent, colorant, dispersant, etc. can improve the antistatic property, colorability and fluidity, etc.; Filling nucleating agent can speed up the crystallization speed, increase the crystallization temperature, form more and smaller spherical crystals, thus improving the transparency and impact strength. Therefore, the filler has a significant effect on improving the performance of plastic products, improving the plastic molding processability and reducing the cost. Application As one of the four general plastic materials, PP has excellent comprehensive performance, good chemical stability, better molding performance and relatively low price; But it also has the strength, modulus, hardness is low, low temperature impact resistance strength is poor, forming shrinkage, easy aging and other shortcomings. Therefore, it must be modified so that it can adapt to the demand of the product. The modification of PP material is generally through adding mineral reinforcement toughening, weather resistance modification, glass fiber reinforcement, flame retardant modification and super toughness modification, and each kind of modified PP has a large number of applications in the field of household appliances. Glass fiber reinforced PP, can be used to make refrigerators, air conditioning refrigeration machines such as axial flow fans and cross flow fans. In addition, it can also be used to manufacture the inner drum of high speed washing machine, wave wheel, belt wheel to adapt to its high requirements on mechanical properties, for the rice cooker base and handle, electronic microwave oven and other places with high requirements on temperature resistance. Glass fiber reinforced PP. Ordinary short glass fiber reinforced PP, because the glass fiber contains short, easy warping, low impact strength, easy deformation when heated, long glass fiber can overcome the above defects of short glass fiber, and the product has a better surface, higher temperature, higher impact strength, can be used in refrigerators and kitchen appliances with high heat resistance. Glass fiber reinforced PP is on the basis of the original pure PP, adding glass fiber and other additives, so as to improve the scope of use of materials. Generally speaking, most glass fiber reinforced materials are used in the structural parts of the product, which is a kind of structural engineering materials. Datasheet Cases Xiamen LFT composite plastic Co., Ltd. Xiamen LFT Composite Plastic Co.,LTD was established in 2009, is a brand-name global suppliers of long fiber reinforced thermoplastic materials integrating product research & development(R&D), production and sale marketing. Our LFT products have passed the ISO9001&16949 system certification and have obtained lots of national trademarks and patents, covering the fields of automotive, military parts and firearms, aerospace, new energy, medical equipment, power wind energy, sports equipment, etc.

- long glass fiber polypropylene high performance

- pp injection molding composite

- PP resin compounds LFT GF

- pp lgf lft thermoplastic resin made in China

- lgf filling pp raw materials sample available

- pp industry use lft green materials

Tags :

-

Xiamen LFT-G High toughness MXD6 composite filling long glass fiber original colorNylon - MXD6 is a kind of crystalline polyamide resin, which is synthesized by the condensation of m-benzoylamine and adipic acid.

- Crystalline nylon resin mxd6 gf good price

- Composite materials with long glass fiber mxd6

- Higher performance plastic mxd6

- Made in China products compounds mxd6

- Customized plastic fiber glass add high sstrength mxd6

- Thermoplastic resin thermoplastic resin

Tags :

e-mail

e-mail English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português العربية

العربية 日本語

日本語 한국의

한국의 中文

中文