-

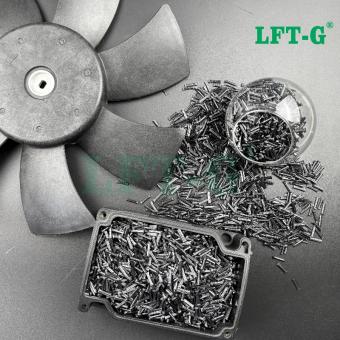

LFT China Manufacturer PPA Long Glass Fiber Reinforced PolymersPPA long glass fiber composites are high-performance thermoplastic materials that combine the durability and strength of glass fiber reinforcement with the superior properties of PPA engineering plastics, making them ideal for demanding industrial applications.

- PPA long glass fiber composite Polyphthalamide

- high-performance PPA polymer

- glass fiber reinforced thermoplastics

- PPA engineering plastic materials

- durable thermoplastic composites

- industrial PPA reinforced polymer

Tags :

-

LFT Polyphenylene Sulfide PPS Manufacturer Glass Fiber filled Compounds engineeing use

- PPS thermoplastic resinforced material

- fiber filling polymer instead of metal steel

- Sample free natural plastic new GFRP

- engineering plastic structural parts

- modified resin good price low MOQ

- Car parts application bearings

Tags :

-

LFT-G modified ABS compounds Long Glass Fiber for automotive partsABS injection molding refers to the process of injecting molten ABS plastic into a mold at high pressures and temperatures. There are many ABS injection molding applications as it is a widely used plastic and can be found in the automotive, consumer product, and construction industries to name a few.

- ABS Long Glass Fiber Reinforced Polymer

- ABS long fiber reinforced

- lgf injection mold abs for engineering

- China manufacturer ABS GF fiber reinforced

- High-performance engineering plastic ABS composite

- Natural color abs materials with filler

Tags :

-

ABS Pellets Glass FiberABS injection molding refers to the process of injecting molten ABS plastic into a mold at high pressures and temperatures. There are many ABS injection molding applications as it is a widely used plastic and can be found in the automotive, consumer product, and construction industries to name a few.

- reinforced glass fiber

- glass fiber reinforced polymer rebar

- glass fiber reinforced concrete panel

- abs plastic

- abs resin pellets

- engineering plastic

Tags :

-

LFT PLA compounds long glass fiber thermoplastic resinPLA (Polylactic Acid) is a semicrystalline thermoplastic polyester. It is derived from renewable sources and is therefore classified as a bioplastic.

- PLA Long fiberglass factory

- Injection molding pla special plastic

- fiber reinfoced plastic pla polymer

- PLA manufacturer good strength

- Special engineering plastic pla

- PLA pure pellets virgin grade lft

Tags :

-

China Carbon Fiber Polyphenylene Sulfide Modified CompoundsPPS is a high-performance, tough engineering plastic with great dimensional and thermal stability, as well as a wide operating temperature range of up to 260 °C and good chemical resistance. Moreover, PPS, like most other thermoplastics, is an electrical insulator. Its ability to be used at high temperatures coupled with its thermal stability makes PPS great for applications such as semiconductor components in machinery, bearings, and valve seats.

- plastic granules price per kg

- long fibre reinforced thermoplastics

- PPS Plastic

- pps melting point

- Injection molding pps

- Engineering plastic

Tags :

-

Polyphthalamide filling long glass fiber injection moldingPolyphthalamide has many uses. It is used for electronics and electrical, automotive, cables & wires, and many other applications.view more

-

LFT-G industry use HDPE filling LGF 30%-60% high toughness pellets 12mm sample freeHDPE Plastic | Long Glass Fiber Reinforced HDPE What is HDPE? High Density Polyethylene (HDPE) is a granular thermoplastic material that is non-toxic, odorless, and highly crystalline (80% - 90%). It has a softening point of 125–135°C and can be used at temperatures up to 100°C. Compared with Low-Density Polyethylene (LDPE), HDPE has superior hardness, tensile strength, creep resistance, wear resistance, electrical insulation, toughness, and cold resistance. It also offers excellent chemical stability, being insoluble in any organic solvents at room temperature and resistant to corrosion from acids, alkalis, and various salts. Long Glass Fiber Reinforced Plastics (LGF) Long glass fiber reinforced plastics (LGF plastics) are created by adding long glass fibers and other additives to pure plastics. This reinforcement significantly improves the material's mechanical and thermal properties, making it suitable for structural and engineering applications. LGF plastics are commonly used with materials such as PP, ABS, PA66, PA6, HDPE, PPA, TPU, PEEK, PBT, and PPS. Advantages of Long Glass Fiber Reinforced Plastics Increased heat resistance: Glass fibers improve the high-temperature performance of plastics, especially in nylon-based materials. Reduced shrinkage and increased rigidity: Fiber reinforcement restricts polymer chain movement, improving dimensional stability. Improved impact resistance: Reinforced plastics resist stress cracking and have higher toughness. Enhanced strength: Tensile, compression, and bending strength are significantly improved due to the high-strength glass fibers. Flame retardancy: Addition of fibers and additives reduces flammability, making most reinforced plastics non-ignitable. HDPE / LGF Datasheet Contact Us For more information about HDPE plastic and long glass fiber reinforced HDPE materials, please contact our sales team. We provide technical support, custom solutions, and sample requests for your industrial and engineering applications.

- HDPE filling long glass fiber white color

- high performance hdpe with lgf

- injection molded plastic hdpe virgin

- Original color 10-12mm hdpe pellets polymer resin

- engineering plastic can be recycled hdpe

- thermoplastic compounds hdpe high rigidity

Tags :

-

Xiamen LFT ABS (Acrylonitrile Butadiene Styrene) Long Glass Fiber Reinforced Thermoplastic CompoundsABS-LGF (Glass Fiber Reinforced ABS) Overview ABS is a versatile engineering plastic known for chemical and thermal stability, strength, toughness, and glossy finish. It is widely used in consumer products such as toys and helmets, as well as automotive applications like interior trim, housings for electronics, and more. Reinforcing ABS with glass fiber significantly improves rigidity, heat resistance, and dimensional stability. ABS-LGF composites provide excellent cost-performance balance, helping manufacturers reduce costs while meeting production needs. About ABS-LGF Compounds Applications of Modified ABS 1. Automotive Parts: Instrument panels, fenders, interiors, lights, mirrors, audio systems. 2. Electronic & Electrical Components: IT and OA equipment shells, converters, power sockets. 3. Electronic Appliances: Switches, controllers, monitors, housings, brackets. 4. Home Appliances: Electrical components, control boxes. Advantages of ABS Injection Molding High Productivity: Efficient, low-waste process ideal for high-volume manufacturing. Complex Part Design: Capable of multi-featured components, including overmolding and metal inserts. Increased Strength: ABS provides excellent mechanical strength and durability. Flexible Color & Material Options: Easily colored, painted, or electroplated to improve environmental resistance. Decreased Waste: Low-wastage production, limited to sprue, runners, and flashing. Low Labor Cost: Highly automated process reduces human intervention and lowers cost per part. Material Details Number ABS-NA-LGF Color Natural or Customized Length 6-25 mm Package 25kg/bag MOQ 25kg Lead Time 2-15 days Port of Loading Xiamen Port Trade Terms EXW / FOB / CFR / CIF / DDU / DDP About Xiamen LFT Founded in 2009, Xiamen LFT Composite Plastics Co., Ltd. is a leading global supplier of long fiber reinforced thermoplastic materials, integrating R&D, production, and marketing. Our products are ISO9001 & IATF16949 certified, patented, and applied in automotive, aerospace, medical, new energy, military, sports equipment, and more. Compared to short fiber thermoplastics (1-2 mm fibers), our LFT materials (5-25 mm fibers) are fully impregnated with resin, ensuring superior mechanical performance. Base resins include PP, PA6, PA66, PPA, PA12, MXD6, PBT, TPU, PPS, ABS, PEEK, etc. Conventional fibers include glass and carbon fibers. Finished products can be used for injection molding, extrusion, or directly replace steel and thermoset components.

- High performance thermoplastic engineering plastics

- excellent heat resistance with filler

- injection molding products light weight

- automotive parts house hold appliances

- modified plastic manufacturer can be customized

- can be recylced GFRP GF30

Tags :

e-mail

e-mail English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português العربية

العربية 日本語

日本語 한국의

한국의 中文

中文