-

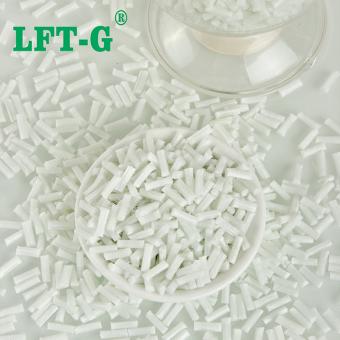

environment reinforced thermoplastic material HDPE lgf compoundHDPE modified pellets injection production material.

- HDPE enhance mateiral

- HDPE modified long fiber pellet

- High density polyethylene compound

- natural color LFT HDPE long glass fiber

- Composite injeciton mold virgin HDPE pellet

- Long glass fiber reinforced hdpe lgf

Tags :

-

LFT HDPE LGF20 Long Fiber Reinforced Thermoplastic CompositeProduct Name:HDPE LGF20, High Density Polyethylene Long Fiber Reinforced Plastic, HDPE Long Fiber Thermoplastic Form: Length about 12mm, High strength, High toughness Advantage: More than 20 years experience product in fiber reinforced plastic .

- HDPE LGF20

- LFT HDPE

- High Density Polyethylene LGF20

- HDPE Long Glass fiber Composite

- High Tensile Strength HDPE LGF

- HDPE Fill Glass Fiber Reinforced Plasitc

Tags :

-

LFT HDPE Long Glass Fiber 30% High Tensile Strength PE LGF30Product Name:HDPE LGF30, High Density Polyethylene Long Glass Fiber Reinforced Plastic Form: Length about 12mm, High Performance LFT Granules Advantage: Contact customer service to obtain TDS, or direct access to the website

- HDPE LGF30

- High Density Polyethylene LGF30

- HDPE Long Glass fiber Reinforced Thermoplastic

- High Tensile Strength HDPE GF30

Tags :

-

LFT HDPE LGF40 Glass Fiber Reinforced Composite For PipeProduct Name:HDPE LGF40, High Density Polyethylene LGF40,Long Glass Fiber Fill HDPE Form: High Impact Toughness, Chemical Resistance, And High Dimensional Stability Advantage:A special laboratory for testing

- HDPE LGF40

- LFT HDPE Composite

- High Density Polyethylene LGF40

- Long Glass fiber Fill HDPE

- High Tensile Strength HDPE GF40

- HDPE Glass Fiber Reinforced Plastic

Tags :

-

LFT High Density Polyethylene Fill Glass Fiber 50% CompositeProduct Name:HDPE LGF50, Glass Fiber Reinforced Plastic Fill HDPE Form: orrosion resistance, compression resistance, warpage resistance Advantage: High quality and low costview more

-

High Density Polyethylene HDPE LGF60 PE Fill Glass Fiber CompositeProduct Name:HDPE LGF60, Polyethylene Long Glass Fiber Reinforced 60% Form: UV resistant and aging resistant Advantage: High quality and low cost

- HDPE LGF60

- High Density Polyethylene LGF60

- HDPE Long Glass Fiber Reinforced Plastic

- Lightweight HDPE GF60

- HDPE Glass Fiber Compound

Tags :

-

Xiamen LFT-G HDPE filling long glass fiber thermoplasitc reinforced compounds natural color for car partsHDPE-LGF High density polyethylene (HDPE)/ glass fiber (LGF) composites were prepared by twin-screw extrusion mechanism, and the mechanical properties and non-isothermal crystallization behavior of HDPE/LGF composites were studied. The results show that the impact strength of the composite can be improved by MAH-g-POE, and the interface bond between the glass fiber and HDPE is good. The Avrami index (n) of the composite does not change with the cooling rate. Datasheet Application Package Xiamen LFT composite plastic Co.,Ltd Come and find us! We will offer you: 1. LFT & LFRT material technical parameters and leading edge design. 2. Mold front design and recommendations. 3. Provide technical support such as injection molding and extrusion molding.

- HDPE filling lgf20

- lgf hdpe composite materials

- reinforced hdpe plastic resin

- long glass fiber hdpe

- Thermoplastic hdpe lgf

- hdpe resin compounds

Tags :

-

LFT-G HDPE filling long glass fiber high toughness and stiffness modified plastic for shellHDPE Introduction High-density polyethylene is an opaque white waxy material, lighter than water, specific gravity of 0.941 ~ 0.960, soft and tough, but slightly harder than LDPE, but also slightly elongated, non-toxic, odorless. Flammable, can continue to burn after leaving the fire, the upper end of the flame is yellow, the lower end is blue, will melt when burning, there are liquid drops, no black smoke, at the same time, emitting the smell of paraffin wax when burning. Acid and alkali resistance, organic solvent resistance, excellent electrical insulation, low temperature, can still maintain a certain degree of toughness. Surface hardness, tensile strength, rigidity and other mechanical strength are higher than LDPE, close to PP, tougher than PP, but the surface finish is not as good as PP. Poor mechanical properties, poor air permeability, easy to deformation, easy to aging, easy to brittle, brittle than PP, easy stress cracking, low surface hardness, easy to scratch. Difficult to print, when printing, surface discharge treatment is required, can not be plated, and the surface is not glossy. HDPE-Long glass fiber Because of its high crystallinity, poor impact strength and environmental cracking resistance and other defects, limiting its scope of application, so a lot of toughening modification HDPE research work has been carried out at home and abroad. Our company has greatly improved the performance of HDPE through the way of co-blending modification. Long fiber reinforced thermoplastic composites are reinforced thermoplastics with fiber lengths greater than 10mm. The reinforcing fibers are mainly glass fibers, carbon fibers, etc. Depending on the type of resin with appropriate fiber surface treatment, better results can be achieved. The addition of fiber material to the resin can greatly improve the overall material performance. Fiber composites absorb external forces in three ways: fiber pullout, fiber breakage, and resin fracture. The increase of fiber length consumes more energy for fiber pull-out, which is beneficial to the improvement of impact strength; the end of fiber in the composite is often the initiation point of crack growth, and the small number of long fiber ends also makes the impact strength increase; the long fiber blends entangle, flip and bend each other when filling the mold, unlike the short fiber blends which are arranged in the flow direction, therefore, the long fiber blends molded products are better than the same molded parts of short fiber blends. Therefore, compared with the same molded parts of short fiber blends, the long fiber blends have higher isotropy, better straightness, less warpage, and therefore better dimensional stability; the heat deflection temperature of long fiber reinforced thermoplastics is also increased than that of short fiber blends. Therefore, long-fiber composites exhibit better performance than short-fiber composites, which can improve rigidity, compression strength, bending strength, and creep resistance. Process TDS for your reference Tests Certifications Quality Management System ISO9001/16949 Certification National Laboratory Accreditation Certificate Modified Plastics Innovation Enterprise Honorary Certificate Heavy metal REACH & ROSH testing Application We will provide technical supports according to your product's images. About us We will offer you: 1. LFT & LFRT material technical parameters and leading edge design. 2. Mold front design ang recommendations. 3. Provide technical support such as injection molding and extrusion molding. Frequently asked questions Q: How to choose the reinforcement method and length of the material when using long fiber reinforced thermoplastic material? A: The selection of materials depend on the requirements of products. It is necessary to assess how much the content is reinforced and how much length is more appropriate, which are depending on the performance requirements of the products. Q: In addition to being suitable for injection molding, long fiber products can be extruded or other processes? A: LFT long glass fiber and long carbon fiber are mainly used for injection molding, and can also extrusion plate profile tube and mold edges a variety of thermoplastic molding methods. Q: The cost of long fiber products is higher than raw materials. Does it has a high recycling value? A: The thermoplastic LFT long fiber material can be recycled and reused very well.

- long glass fiber HDPE

- long fibre reinforced thermoplastics

- glass fiber reinforced plastics granules

- LFT composite

- HDPE LGF

- Glass fiber fill hdpe

Tags :

-

Xiamen LFT-G High Density Polyethylene HDPE LGF60 Fill Long Glass Fiber Composite materialsProduct Name:HDPE LGF60, Polyethylene Long Glass Fiber Reinforced 60% Form: UV resistant and aging resistant Advantage: High quality and low cost

- HDPE LGF60 recycled plastic

- LFT HDPE Composite pure plastic virgin grade

- Lightweight HDPE GF60 application

- HDPE Glass Fiber Compounds

Tags :

-

Xiamen LFT-G HDPE filling long glass fiber high toughness stiffness modified pellets for shellHDPE Introduction High-density polyethylene is an opaque white waxy material, lighter than water, specific gravity of 0.941 ~ 0.960, soft and tough, but slightly harder than LDPE, but also slightly elongated, non-toxic, odorless. Flammable, can continue to burn after leaving the fire, the upper end of the flame is yellow, the lower end is blue, will melt when burning, there are liquid drops, no black smoke, at the same time, emitting the smell of paraffin wax when burning. Acid and alkali resistance, organic solvent resistance, excellent electrical insulation, low temperature, can still maintain a certain degree of toughness. Surface hardness, tensile strength, rigidity and other mechanical strength are higher than LDPE, close to PP, tougher than PP, but the surface finish is not as good as PP. Poor mechanical properties, poor air permeability, easy to deformation, easy to aging, easy to brittle, brittle than PP, easy stress cracking, low surface hardness, easy to scratch. Difficult to print, when printing, surface discharge treatment is required, can not be plated, and the surface is not glossy. HDPE-Long glass fiber Because of its high crystallinity, poor impact strength and environmental cracking resistance and other defects, limiting its scope of application, so a lot of toughening modification HDPE research work has been carried out at home and abroad. Our company has greatly improved the performance of HDPE through the way of co-blending modification. Long fiber reinforced thermoplastic composites are reinforced thermoplastics with fiber lengths greater than 10mm. The reinforcing fibers are mainly glass fibers, carbon fibers, etc. Depending on the type of resin with appropriate fiber surface treatment, better results can be achieved. The addition of fiber material to the resin can greatly improve the overall material performance. Fiber composites absorb external forces in three ways: fiber pullout, fiber breakage, and resin fracture. The increase of fiber length consumes more energy for fiber pull-out, which is beneficial to the improvement of impact strength; the end of fiber in the composite is often the initiation point of crack growth, and the small number of long fiber ends also makes the impact strength increase; the long fiber blends entangle, flip and bend each other when filling the mold, unlike the short fiber blends which are arranged in the flow direction, therefore, the long fiber blends molded products are better than the same molded parts of short fiber blends. Therefore, compared with the same molded parts of short fiber blends, the long fiber blends have higher isotropy, better straightness, less warpage, and therefore better dimensional stability; the heat deflection temperature of long fiber reinforced thermoplastics is also increased than that of short fiber blends. Therefore, long-fiber composites exhibit better performance than short-fiber composites, which can improve rigidity, compression strength, bending strength, and creep resistance. Process TDS for your reference Tests Certifications Quality Management System ISO9001/16949 Certification National Laboratory Accreditation Certificate Modified Plastics Innovation Enterprise Honorary Certificate Heavy metal REACH & ROSH testing Application We will provide technical supports according to your product's images. About us We will offer you: 1. LFT & LFRT material technical parameters and leading edge design. 2. Mold front design ang recommendations. 3. Provide technical support such as injection molding and extrusion molding. Frequently asked questions Q: How to choose the reinforcement method and length of the material when using long fiber reinforced thermoplastic material? A: The selection of materials depend on the requirements of products. It is necessary to assess how much the content is reinforced and how much length is more appropriate, which are depending on the performance requirements of the products. Q: In addition to being suitable for injection molding, long fiber products can be extruded or other processes? A: LFT long glass fiber and long carbon fiber are mainly used for injection molding, and can also extrusion plate profile tube and mold edges a variety of thermoplastic molding methods. Q: The cost of long fiber products is higher than raw materials. Does it has a high recycling value? A: The thermoplastic LFT long fiber material can be recycled and reused very well.

- long glass fiber HDPE instead metal and steel

- LFT composite PE for pipe undergrund

- HDPE LGF sample available injection mold

- Glass fiber fill hdpe virgin grade

Tags :

-

Xiamen LFT-G High Density Polyethylene Plastic filled long glass fiber reinforced compounds natural colorHDPE-LGF High density polyethylene (HDPE)/ glass fiber (LGF) composites were prepared by twin-screw extrusion mechanism, and the mechanical properties and non-isothermal crystallization behavior of HDPE/LGF composites were studied. The results show that the impact strength of the composite can be improved by MAH-g-POE, and the interface bond between the glass fiber and HDPE is good. The Avrami index (n) of the composite does not change with the cooling rate. Datasheet Application Package Xiamen LFT composite plastic Co.,Ltd Come and find us! We will offer you: 1. LFT & LFRT material technical parameters and leading edge design. 2. Mold front design and recommendations. 3. Provide technical support such as injection molding and extrusion molding.view more

-

Xiamen LFT-G HDPE filling long glass fiber thermoplasitc reinforced compoundsHDPE-LGF High density polyethylene (HDPE)/ glass fiber (LGF) composites were prepared by twin-screw extrusion mechanism, and the mechanical properties and non-isothermal crystallization behavior of HDPE/LGF composites were studied. The results show that the impact strength of the composite can be improved by MAH-g-POE, and the interface bond between the glass fiber and HDPE is good. The Avrami index (n) of the composite does not change with the cooling rate. Datasheet Application Package Xiamen LFT composite plastic Co.,Ltd Come and find us! We will offer you: 1. LFT & LFRT material technical parameters and leading edge design. 2. Mold front design and recommendations. 3. Provide technical support such as injection molding and extrusion molding.view more

e-mail

e-mail English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português العربية

العربية 日本語

日本語 한국의

한국의 中文

中文