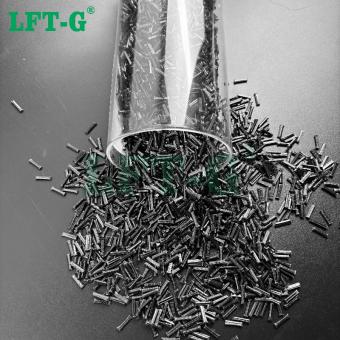

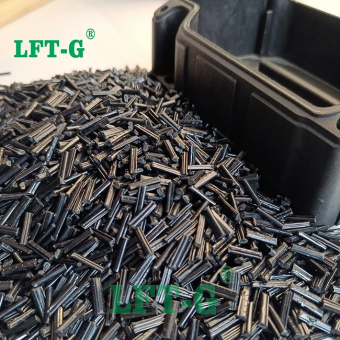

Long carbon fiber is a new material with high strength and high modulus and excellent mechanical properties. It is a microcrystalline graphite material obtained by carbonization and graphitization of organic fibers. Its specific gravity is less than 1/4 of steel, and its strength is higher than that of steel. Corrosion resistant, high modulus, no melting. And a variety of resin substrates after impregnation extrusion molding into pellets, long carbon fiber polymer. Can be used for direct molding products. In recent years, it has been widely used in aerospace, mechanical and electronic chemicals.

-

PLA Carbon FiberLFR-PLA can be processed using conventional plastic processing techniques like injection molding and extrusion, offering good adaptability in manufacturing. It is widely used in industries like automotive, consumer electronics, 3D printing, and eco-friendly packaging due to its combination of high performance and sustainability.

- pla carbon fiber

- pla carbon fiber filament

- carbon fiber pla filament

- pla pellets

- carbon fiber reinforced polymer

- carbon compounds

Tags :

-

PEEK Carbon FiberPure PEEK itself is a special engineering plastic, with radiation resistance, self-lubrication, high temperature resistance, wear resistance, fatigue resistance and other characteristics. The performance of carbon fiber reinforced PEEK material has improved in many aspects compared with pure PEEK material.

- peek polymer

- carbon fiber polymer

- peek polymer properties

- carbon fiber reinforced polymer composites

- carbon fiber reinforced polymer structure

Tags :

-

PP Copolymer Carbon FiberThe modified polypropylene material reinforced by carbon fiber has a series of advantages, such as light weight, high modulus, high specific strength, low coefficient of thermal expansion, high temperature resistance, heat shock resistance, corrosion resistance, good vibration absorption, etc., and can be applied to auto parts such as automobile sub-instrument assembly.

- pp polymer

- fiber polymer

- fiber reinforced polymer

- fiber reinforcement polymer

- fiber reinforced polymer composite

Tags :

-

Polypriopylene PP Carbon FiberPP long carbon fiber reinforced material offers exceptional strength and lightweight properties, making it ideal for high-performance applications. Its superior rigidity and impact resistance enhance product durability and structural integrity. Widely used in automotive, drones, and industrial components, it ensures excellent mechanical performance.

- PP CF30

- Polypropylene granules manufacturer

- PP copolymer pellets

- copolymer vs homopolymer pp

- pp carbon fiber compound

- Carbon Fiber Reinforced Materials

Tags :

-

PA12 Carbon FiberPA12 Long Carbon Fiber (LCF) reinforced composite is a high-performance engineering thermoplastic material based on a Polyamide 12 (PA12) matrix, reinforced with continuous long carbon fibers. This material combines the excellent toughness, low moisture absorption, and chemical resistance of PA12 with the superior strength, stiffness, and fatigue resistance provided by long carbon fibers. It is designed for advanced lightweight structural applications.view more

-

PA6 Carbon FiberCompared to short fiber counterparts, this composite offers superior load-bearing capability and long-term durability under dynamic stress conditions. Its balanced properties make it ideal for structural components in the automotive, aerospace, power tool, and industrial sectors, where lightweight yet robust materials are essential.view more

-

PA66 Carbon FiberThe carbon fiber reinforcement improves strength, impact resistance, and overall structural integrity, making it ideal for critical applications. With excellent thermal stability and chemical resistance, it's well-suited for high-temperature and harsh environments. This lightweight material provides a cost-effective alternative to metals, ensuring reliable long-term performance.view more

-

PP Carbon FiberThe modified polypropylene material reinforced by carbon fiber has a series of advantages, such as light weight, high modulus, high specific strength, low coefficient of thermal expansion, high temperature resistance, heat shock resistance, corrosion resistance, good vibration absorption, etc., and can be applied to auto parts such as automobile sub-instrument assembly.view more

-

LFT PLA Manufacturer Carbon Fiber filled Compounds green materialsPLA is an opaque plastic suitable for making medical components as well as for prototyping applications. PLA is a high-strength but brittle plastic that cannot be used in applications that experience shock loads. The lactic acid building blocks of PLA can be made from fermented plant starch, like corn, under controlled conditions. It takes less energy to produce PLA than petroleum-based thermoplastics, making it relatively eco-friendly. PLA is often regarded as being biodegradable. What Are the Advantages of PLA? Some of the advantages of PLA plastic are listed below: Biocompatibility: PLA is non-toxic to humans. It can remain in contact with the skin for long periods without any negative effects. The decomposition products of PLA are also non-toxic: it degrades into harmless lactic acid. It is often used for stents and sutures that are designed to break down inside the body over several months. Low-Energy for Production: PLA takes less energy to produce compared to other petroleum-based plastics due to its relatively low melting point of 165 °C. The polymerization of PLA also consumes 25 to 55 % less energy than other conventional petroleum-based polymers. Mechanical Properties: PLA has good room temperature strength and stiffness, but is not suitable for sudden impact loads. Food Safe: PLA is non-toxic and is generally recognized as safe by the FDA (Food and Drug Administration). FAQ *What processes are LFT materials suitable for? LFT material is mainly suitable for injection molding, as well as partial extrusion. The requirements for injection molding machines are mainly reflected in the nozzle. *Why are your products so long? Why does the material I used before, filled with glass fiber, look different than this? Although long fiber modified materials (LFT) and short fiber modified materials (SFT) are through the combination of fiber and resin to produce higher properties of the complex. However, the two materials are different from the production process, internal structure, appearance, performance, application and so on. Production process: The fiber of SFT is chopped and mixed with resin, and the production process of LFT is melt impregnation. Internal structure: The fibers inside SFT particles are short and disordered, while the fibers inside LGF are neatly arranged and longer. Appearance: The length of SFT is usually less than 3 mm, and the length of LFT is 5-24mm. Performance: LFT impact performance than SFT increased 1-3 times, tensile strength increased by more than 50%, mechanical properties improved by 50-80%. Application: LFT is more suitable for use in products with high strength requirements, as load-bearing parts and structural parts. *What is your MOQ? MOQ is 25kg *Do you support custom service? Color: Please let us know which Pantone color you want to customize Length: Lengtjh between 5mm-24mm can be customized. If there are no special requirements, the length of the plastic particles is 10-12 mm. Our custom service is free, but the MOQ is 500kg. *Where is your factory? At present, our company headquarters and factory are in Xiamen, China. We also have several offices in other provinces in China, and an exclusive agent in Turkey.

- PLA recycled

- fiber filling polymer instead of metal steel

- Sample free natural plastic new CFRP

- PLA Carbon

- China manufacturer PLA

- pla resin customized service

Tags :

-

Advanced Carbon Materials Polyetheretherketone Resin Long Carbon Fiber Reinforced PelletsPEEK long carbon fiber reinforced material provides exceptional thermal stability, outstanding chemical resistance, and superior mechanical properties, making it ideal for the most demanding engineering applications. With its high strength, rigidity, and low friction characteristics, this material is widely used in aerospace, automotive, and industrial sectors. Its ability to withstand extreme temperatures and harsh chemical environments ensures reliable performance and durability in critical applications.

- peek automotive industry

- uses of peek in automotive industry

- peek composite

- peek pellets

- carbon fiber reinforced peek market

- peek-cf

Tags :

-

Advanced Carbon Materials Polyphenylene Sulfide PelletsPPS long carbon fiber reinforced material features outstanding thermal stability, exceptional chemical resistance, and excellent mechanical strength, making it ideal for high-performance engineering applications. With superior stiffness, low moisture absorption, and inherent flame retardancy, this material is widely used in automotive, aerospace, and electrical industries. Its high strength and dimensional stability ensure reliable performance even in extreme environments.

- China manufacturer carbon fiber compounds

- PPS raw materials

- PA12 black carbon

- pps resin suppliers

- pps plastic melting point

- pps-cf

Tags :

e-mail

e-mail English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português العربية

العربية 日本語

日本語 한국의

한국의 中文

中文