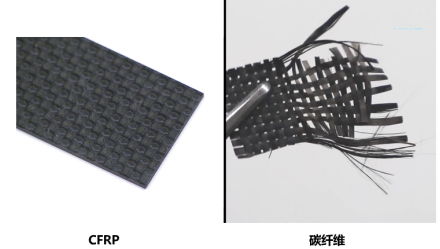

Carbon fiber is known as the "king of materials" and "black gold" in the industry. It has the characteristics of light weight, high strength and corrosion resistance, and is widely used in aviation, aerospace, energy, transportation, wind power blades, construction bridges, military equipment and other fields, is an important material for national defense and civil production and life.

In recent years, as the carbon fiber industry has entered a period of rapid development, the application of carbon fiber composites has been increasing, and the production process has produced more and more waste. Industry experts point out that all aspects of the carbon fiber industry chain will produce waste, and the scrap rate in the production and manufacturing process alone is as high as 30% to 50%. Moreover, CFRP is difficult to repair, and even part of the damage will be discarded.

Since carbon fiber composites cannot be degraded under natural conditions, a large amount of scrap and waste can only be landfilled. According to statistics, the global carbon fiber use in 2018 alone reached 92,600 tons, of which, the scrap amount was 30,300 tons. This will not only cause pollution to the environment, but also is a great waste of resources.

Ambient temperature CFRP decomposition and recycling technology

The research team has developed a technology that can simply decompose CFRP at low temperature. By soaking CFRP in the solution, carbon fibers can be separated from resin in a short time, and the resin raw material can be recycled at the same time.

This technology is a revolutionary new technology to return the hard-to-process CFRP back to the raw material and recycle it all. This technology is inspired by the structure of the redox reaction that occurs in the human body.

The reason for the strength of CFRP is the combination of carbon fiber and plastic. Carbon fibers do not break easily and are strong, but they bend easily. If carbon fibers are bonded with resin, it becomes an excellent material with both lightness and strength, achieving a powerful combination of carbon fibers and plastic of amazing strength, but on the contrary, it is also a big obstacle to recycling.

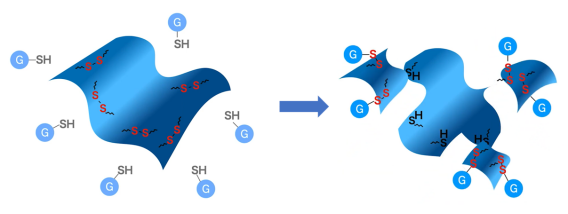

The thermosetting plastic used in CFRP, once solidified, is very difficult to decompose and can only be disposed of by burning or landfilling for a long time. Previously, there was the use of the agent mercaptoethanol, which can destroy the S-S bond within CFRP, for recycling, but the agent is too toxic and neither safe nor environmentally friendly.

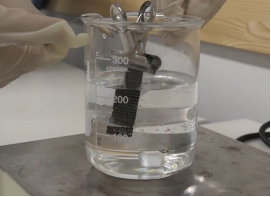

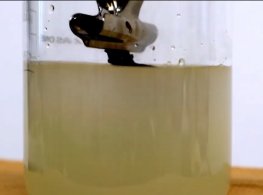

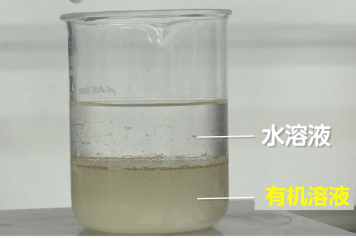

The R&D team turned their attention to a natural biomaterial, which was dissolved in water and then added to an organic solvent, into which CFRP was placed, and the resin in CFRP was dissolved into the liquid phase after stirring for several hours at room temperature.

The principle is that the nature of the bio-structured material was used to reorganize the S-S bond in the CFRP and replace the S-S bond in the resin, and the decomposed resin was dissolved in the organic solvent.

Decomposition is achieved by replacing the S-S key in the CFRP

CFRP is impregnated in solvent → after stirring for 3 hours → resin is completely dissolved and carbon fiber is completely separated out → solution after CFRP decomposition

This technology, which can decompose and reuse strong CFRP by simply adding biological materials to the solution without using harmful agents, is expected to be the key to the popularity of CFRP in the age of energy conservation and environmental protection.