-

HDPE injection molding long glass fiber compoundsOur long glass fiber reinforced HDPE material offers exceptional strength, impact resistance, and dimensional stability, making it ideal for structural and industrial applications. Designed for lightweight performance and durability, it’s widely used in automotive, logistics, and heavy-duty injection molded parts.

- HDPE GF reinforced

- fiber-reinforced polymers (FRP)

- OEM HDPE composite manufacturer

- PE LGF manufacturer

- chemical-resistant HDPE

- high stiffness HDPE for engineering applications

Tags :

-

LFT PLA compounds long glass fiber thermoplastic resinPLA (Polylactic Acid) is a semicrystalline thermoplastic polyester. It is derived from renewable sources and is therefore classified as a bioplastic.

- PLA Long fiberglass factory

- Injection molding pla special plastic

- fiber reinfoced plastic pla polymer

- PLA manufacturer good strength

- Special engineering plastic pla

- PLA pure pellets virgin grade lft

Tags :

-

High Temperature Resistance PPA Glass Fiber Polymer Wide ApplicationsPolyphthalamide (PPA) is a semicrystalline, aromatic polyamide. It is in the polyamide, or nylon, family. Compared to Nylon 6/6, it is stronger, stiffer, less sensitive to moisture, and has higher thermal capabilities. In addition, it has significant resistance to chemical fatigue and mechanical creep.

- Reinforced PPA plastic

- PPA injection molding material

- Electronic components thermoplastic

- ppa glass fiber

- glass fibre vs carbon fibre

- aerospace polymer

Tags :

-

High Mechanical Properties Nylon MXD6 Long Glass Fiber Polymer PelletsWith its unique balance of strength, barrier performance, and stability, MXD6-LGF is the ideal solution for demanding applications.view more

-

Polypropylene long carbon fiber filled PP high mechanical properties polymerThe modified polypropylene material reinforced by carbon fiber has a series of advantages, such as light weight, high modulus, high specific strength, low coefficient of thermal expansion, high temperature resistance, heat shock resistance, corrosion resistance, good vibration absorption, etc., and can be applied to auto parts such as automobile sub-instrument assembly.

- carbon fiber reinforced plastic

- plastic injection molding materials

- carbon fiber reinforced polymer automotive

- reinforced composite materials

- pp injection molding

- fiber reinforced composite

Tags :

-

Xiamen LFT-G Long Carbon Fiber Reinforced PEEK Composite Injection ModingPEEK filling long carbon fiber reinforced thermoplastic for lightweight car parts.

- Peek carbon fiber reinforced pellet

- Carbon fiber PEEK granules aerospace automotive parts

- Carbon fiber composite peek granules

- Plastic peek carbon fiber polymers peek resin

- Black color peek carbon fiber granules

- Black color peek carbon fiber plastic

Tags :

-

Long glass fiber filled Polypropylene reinforced plastic pelletsGrade: General grade, Heat-resistant grade, UV-resistant grade, Toughen resistant grade Fiber specification: 20%-70%

- general grade modified PP GF30

- Heat-resistant grade long cut PP polymers

- UV-resistant grade PP LFT for home appliances

- Toughen resistant grade PP with filler glass fiber

- Injection grade PP compounds instead metal

- Wide application range PP thermoplastic resin

Tags :

-

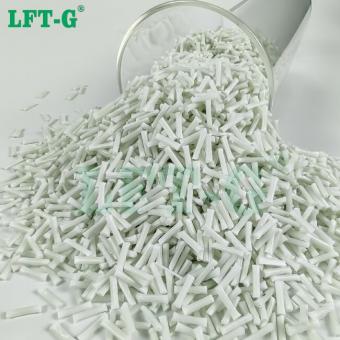

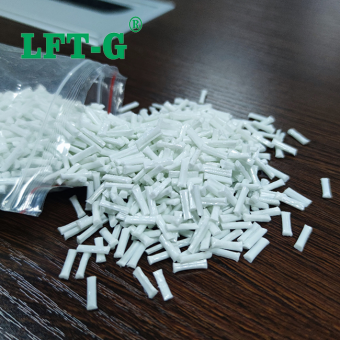

PLA Polylactic acid compounds long glass fiber thermoplastic resin for engineeringPLA & LGFPLA – Eco-Friendly and Reinforced Bioplastics PLA (Polylactic Acid) is a non-natural polyester and one of the most promising "green plastics." Known for its biocompatibility, biodegradability, and high mechanical strength, PLA can be completely degraded by microorganisms into CO₂ and water, making it non-toxic and environmentally friendly. PLA offers mechanical properties similar to polypropylene, while providing the gloss, clarity, and processability of polystyrene. With a lower processing temperature than polyolefins, PLA can be molded via injection molding, extrusion, blow molding, spinning, and other general plastic processes. Its applications range from disposable packaging and fibers to nonwovens, and extend to medical, chemical, pharmaceutical, and 3D printing industries. Long Glass Fiber Reinforced PLA (LGFPLA) Glass fiber is an inorganic non-metallic material with excellent insulation, heat resistance, corrosion resistance, and mechanical strength. When used to reinforce PLA, it creates Long Glass Fiber PLA (LGFPLA), a high-performance thermoplastic composite with glass fibers 10–25mm long, forming a 3D structure for superior strength and stability. LGFPLA is available as columnar pellets, typically 12mm (for injection molding) or 25mm (for compression molding) in length, with glass fiber content from 20% to 60%. Colors can be customized to match client requirements. Advantages of LGF vs SGF (Long Fiber vs Short Fiber PLA) Longer fiber length improves mechanical properties and part durability. High specific stiffness and strength, with excellent impact resistance — ideal for automotive parts. Improved creep resistance and dimensional stability for precise molding. Outstanding fatigue resistance and long-term reliability. Stable performance in high temperature and humid environments. Minimal fiber damage during molding due to fiber mobility within the mold. Technical Specifications Product Number Color Length Fiber Specification Package Sample Port of Loading Delivery Time PLA-NA-LGF Natural or customizable 6–25mm 20%–60% 25kg/bag Available Xiamen Port 7–15 days after shipment Lab & Factory Xiamen LFT Composite Plastic Co., Ltd. Xiamen LFT Composite Plastic Co., Ltd. specializes in developing and producing long glass fiber (LGF) and long carbon fiber (LCF) reinforced thermoplastic composites (LFT-G, LFRT, LFT). Our materials are lightweight, high-strength, impact-resistant, and environmentally friendly, offering excellent corrosion and chemical resistance along with superior molding performance. Our products are used across industries including automotive, aerospace, military, electrical, medical, sports equipment, and daily consumer goods, producing components such as gears, rollers, pulleys, pump impellers, fan blades, and more.

- PLA reinforced plastic lgf production pla

- LFT-G PLA injection mold modified materials

- long glass fiber compounds pla resin basic

- PLA pellets of long fiber 30 made in China

- Self owing PLA polymers manufacturer direct sell

Tags :

-

LFT-G industry use HDPE filling LGF 30%-60% high toughness pellets 12mm sample freeHDPE Plastic | Long Glass Fiber Reinforced HDPE What is HDPE? High Density Polyethylene (HDPE) is a granular thermoplastic material that is non-toxic, odorless, and highly crystalline (80% - 90%). It has a softening point of 125–135°C and can be used at temperatures up to 100°C. Compared with Low-Density Polyethylene (LDPE), HDPE has superior hardness, tensile strength, creep resistance, wear resistance, electrical insulation, toughness, and cold resistance. It also offers excellent chemical stability, being insoluble in any organic solvents at room temperature and resistant to corrosion from acids, alkalis, and various salts. Long Glass Fiber Reinforced Plastics (LGF) Long glass fiber reinforced plastics (LGF plastics) are created by adding long glass fibers and other additives to pure plastics. This reinforcement significantly improves the material's mechanical and thermal properties, making it suitable for structural and engineering applications. LGF plastics are commonly used with materials such as PP, ABS, PA66, PA6, HDPE, PPA, TPU, PEEK, PBT, and PPS. Advantages of Long Glass Fiber Reinforced Plastics Increased heat resistance: Glass fibers improve the high-temperature performance of plastics, especially in nylon-based materials. Reduced shrinkage and increased rigidity: Fiber reinforcement restricts polymer chain movement, improving dimensional stability. Improved impact resistance: Reinforced plastics resist stress cracking and have higher toughness. Enhanced strength: Tensile, compression, and bending strength are significantly improved due to the high-strength glass fibers. Flame retardancy: Addition of fibers and additives reduces flammability, making most reinforced plastics non-ignitable. HDPE / LGF Datasheet Contact Us For more information about HDPE plastic and long glass fiber reinforced HDPE materials, please contact our sales team. We provide technical support, custom solutions, and sample requests for your industrial and engineering applications.

- HDPE filling long glass fiber white color

- high performance hdpe with lgf

- injection molded plastic hdpe virgin

- Original color 10-12mm hdpe pellets polymer resin

- engineering plastic can be recycled hdpe

- thermoplastic compounds hdpe high rigidity

Tags :

-

LFT-G engineering plastic PBT filling long glass fiber 20%-60% reinforced materials high mechanical properties good pricePBT Plastic | Long Glass Fiber Reinforced PBT (PBT-LGF) What is PBT? Polybutylene terephthalate (PBT) is a semi-crystalline engineering thermoplastic polyester. It is produced via polycondensation of 1,4-butylene glycol and terephthalic acid (PTA) or dimethyl terephthalate (DMT), forming a milky white translucent to opaque resin. PBT exhibits excellent mechanical strength, chemical resistance, thermal stability, and electrical insulation properties, making it ideal for demanding engineering applications. Basic Properties of PBT Specific gravity: 1.31 g/cm³ Melting point: 225~275°C Glass transition temperature (Tg): 22–43°C Rockwell hardness (R scale): 118 Water absorption: 0.34% Molding shrinkage: 1.7~2.3% PBT-LGF | Long Glass Fiber Reinforced PBT PBT-LGF combines PBT with long glass fibers, improving mechanical strength, fatigue resistance, dimensional stability, and creep resistance. These properties are maintained even under high-temperature conditions. Advantages of PBT-LGF Excellent mechanical strength and fatigue resistance High heat resistance: UL temperature index 120–140°C Good solvent resistance and no stress cracking Easy flame-retardant processing: UL94 V-0 achievable Excellent electrical insulation: high resistivity, dielectric strength, arc resistance Good molding and secondary processing: injection molding and extrusion Fast crystallization and good fluidity: thin walls can be processed in seconds PBT-LGF Technical Data Sheet (TDS) Applications of PBT-LGF Long glass fiber reinforced PBT is widely used in electronics, automotive, and industrial applications due to its high mechanical strength, heat resistance, electrical insulation, and dimensional stability. Electronics: fuse-less wire breakers, electromagnetic switches, transformers, appliance handles, connectors, housings Automotive: door handles, bumpers, distributor covers, fenders, wire guard shells, wheel covers Industrial parts: OA fans, keyboards, fishing reels, lampshades, and other mechanical components Processing of PBT-LGF PBT-LGF can be easily processed via injection molding or extrusion using standard equipment. Due to fast crystallization and good fluidity, mold temperatures are lower than other engineering plastics, enabling rapid processing of both thin-walled and large parts. PBT-LGF Product Details Number Color Length Sample MOQ Package Port of Loading Delivery time PBT-NA-LGF30 Natural color (customizable) 12mm (customizable) Available 1 ton 25kg/bag Xiamen Port 7-15 days after shipment Lab & Factory Frequently Asked Questions Q: Does long glass fiber injection require special molding machines or molds? A: Yes. Injection molding machines, screws, nozzles, and mold structures must meet long fiber reinforcement requirements. Q: How to prevent rough surfaces or floating fibers in PBT-LGF injection molding? A: Ensure plastic particles are fully dried and plasticized, adjust mold temperature appropriately, and polish mold surfaces for smooth finishes.

- PBT pellets lgf 30 polymer

- LFT PBT modified plastic glass fiber

- reinforced PBT for car parts gfrp

- self owing pbt pellets

- best price PBT glass fiber compounds

- composite pbt-lgf sample free

Tags :

-

PP filling Long carbon fiber injection molding high toughnessThe modified polypropylene material reinforced by carbon fiber has a series of advantages, such as light weight, high modulus, high specific strength, low coefficient of thermal expansion, high temperature resistance, heat shock resistance, corrosion resistance, good vibration absorption, etc., and can be applied to auto parts such as automobile sub-instrument assembly.

- PP pellets lcf 30 polymer

- PP recycled for car parts electric parts

- Long carbon fiber Reinforced Polypropylene for electrial accessories

- LFT-G xiamen compounds pp plastic resin

- PP green materials instead metal

- Polypropylene filled lcf 30 40 50

Tags :

-

LFT modified Polyamide 6 reinforced plastic long carbon fiber thermoplastic resinPolyamide 6 (PA6) Material Polyamide 6 (PA6) has chemical and physical properties very similar to PA66. However, differences in molecular structure lead to distinct performance characteristics. PA6 features a lower melting point and a wider processing temperature window, offering better impact resistance and solubility resistance than PA66, while also exhibiting higher moisture absorption. Since many quality characteristics of plastic parts are affected by hygroscopicity, molding shrinkage is largely influenced by crystallinity and moisture absorption. Therefore, these factors must be carefully considered when designing PA6 products. Fiber-reinforced PA6 effectively reduces shrinkage and mitigates issues caused by moisture absorption. Its high crystallinity and excellent flowability contribute to improved dimensional stability and overall part performance. Datasheet Nylon products should be used with attention to dimensional deviation caused by thermal expansion and moisture absorption. Conventional PA6 also shows limited acid resistance and UV resistance. Long-term exposure to high temperatures may cause thermal oxidation, resulting in discoloration and eventual material degradation. Therefore, unmodified nylon is generally not recommended for outdoor applications. Carbon fiber reinforced modified PA6 significantly improves creep resistance, rigidity, wear resistance, and mechanical strength, enabling stable performance in outdoor and demanding environments. *Tip: Poor compatibility between carbon fiber and PA6 may lead to fiber floating and reduced mechanical properties. Xiamen LFT’s PA6 composites feature excellent fiber–matrix compatibility, effectively avoiding these issues. Advantages Strength & Durability: Excellent balance of rigidity and heat resistance Optimized Design: Superior surface appearance suitable for complex structures Excellent Processability: High flowability and thermal stability for precision molding High Thermal Stability: Reliable performance under elevated temperatures Stable Electrical Properties: Consistent insulation across wide temperature and frequency ranges Applications Long carbon fiber reinforced PA6 enhances strength, heat resistance, impact resistance, and dimensional stability, making it suitable for both industrial and consumer applications. With trends toward lightweight and compact automotive design, under-the-hood temperatures continue to rise. Carbon fiber reinforced PA6 meets these demanding requirements and is widely used in automotive engine components, electrical systems, body structures, and airbag-related parts. Due to its excellent mechanical properties, dimensional stability, heat resistance, and aging resistance, carbon fiber reinforced PA6 is also commonly applied in mechanical parts and aerospace equipment components. Long carbon fiber reinforced PA6 features high flowability, high rigidity, excellent mechanical strength, low shrinkage, creep resistance, thermal stability, wear resistance, oil resistance, uniform fiber dispersion, and good surface gloss. Typical applications include power tools, fishing equipment, automotive parts, machinery components, and office accessories. Certifications ISO 9001 & IATF 16949 Quality Management System Certification National Laboratory Accreditation Certificate Modified Plastics Innovation Enterprise REACH & RoHS Heavy Metal Compliance Factory Contact Us

- pa6 lcf granules high rigidity strength

- PA6 long carbon fiber extrusion or injection molding

- thermoplastic resin pa6 with fiber natural black

- Nylon composite pellets Polymer granules PA6

- LFT-G pellets pa6 low warping

Tags :

e-mail

e-mail English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português العربية

العربية 日本語

日本語 한국의

한국의 中文

中文