HDPE has a higher density compared to other polyethylene variants, making it more rigid and stronger.

HDPE has a higher density compared to other polyethylene variants, making it more rigid and stronger.

item no.:

HDPE-NA-LGFPayment:

Discussedproduct origin:

ChinaColor:

Natural color or Customizedshipping port:

XiamenLead Time:

2-10 working days

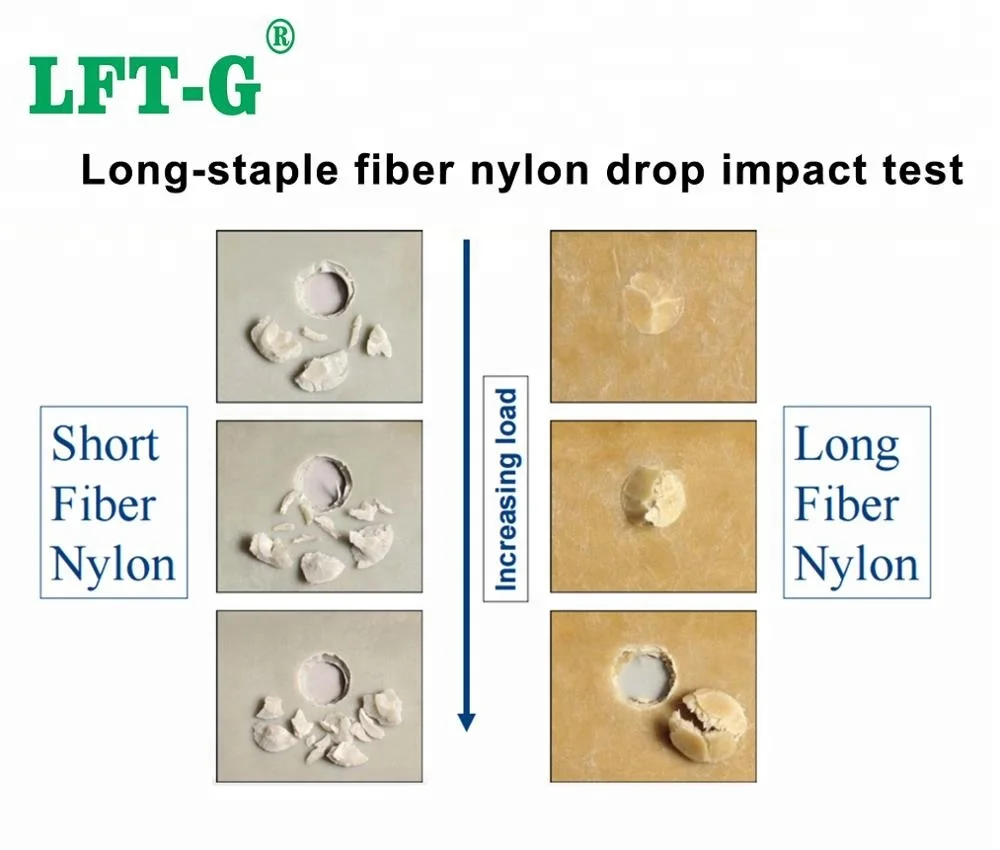

Long fiber pellets have several significant advantages over short fiber materials, especially in enhancing the mechanical properties of plastics. Our long fiber pellets are typically used to improve the strength, rigidity, and impact resistance of materials. They are longer than short fiber pellets, allowing for better dispersion and forming a stronger fiber network structure, which greatly enhances tensile and bending strength.

Compared to short fibers, long fiber materials offer the following differences:

Long Fiber Reinforced PLA (LFR‑PLA) is an engineering plastic that combines long glass fibers with PLA resin. PLA is biodegradable but naturally limited in strength, toughness, and heat resistance. Long glass fiber reinforcement significantly improves PLA performance, making it suitable for more demanding applications.

The added long glass fibers greatly enhance strength, stiffness, impact resistance, and thermal performance—making LFR‑PLA suitable for automotive parts and electronic housings.

LFR‑PLA also provides better wear and corrosion resistance, ideal for high‑friction applications such as sporting goods and machinery. Being PLA‑based, it offers environmental benefits, making it attractive for sustainable industries like packaging and medical devices.

It can be processed via injection molding and extrusion, commonly used in automotive, consumer electronics, 3D printing, and eco‑friendly packaging.

Q: Does long glass fiber and long carbon fiber injection require special injection molding machines or molds?

A: Yes. Product design, screw/nozzle of the injection machine, mold flow path and structure must consider long‑fiber requirements.

Q: What are the main features and advantages of long fiber reinforced thermoplastics?

A: Compared with short fibers, LFT‑G long glass fiber and long carbon fiber materials offer high mechanical strength, high impact resistance, and high tensile modulus. Suitable for large structural parts. Applicable for injection molding and extrusion.

Q: Are long fiber composites suitable for processes other than injection molding?

A: Yes. Long fiber materials can be used for extrusion of sheets, profiles, pipes, and molding. Injection molding is the most common.