PA66 Product Information

Product Information

PA66, also known as Polyamide 66 or Nylon 66, is made from adipic acid and hexamethylenediamine through condensation polymerization.

As the most widely used polyamide, PA66 appears translucent or opaque and offers excellent wear resistance, self-lubrication, high mechanical strength, rigidity, heat resistance, low friction coefficient, and strong impact resistance.

PA66 maintains strength and stiffness at higher temperatures and resists acids, alkalis, most inorganic salt solutions, alkyl halides, hydrocarbons, esters, ketones, etc. However, it is soluble in polar solvents such as phenol and formic acid.

Compared with PA6, PA66 has better wear resistance, higher melting point, and higher thermal deformation temperature, but higher water absorption and lower dimensional stability. Hygroscopic effects must be considered in product design.

Mechanical properties can be improved by adding modifiers such as glass fiber or carbon fiber. PA66 can also form alloy resins, with a suitable compatibilizer being key to forming tough nylon.

According to IHS, about 60% of PA66 is used in engineering plastics; 88% is processed by injection molding, while 12% is processed via extrusion, blow molding, and other methods.

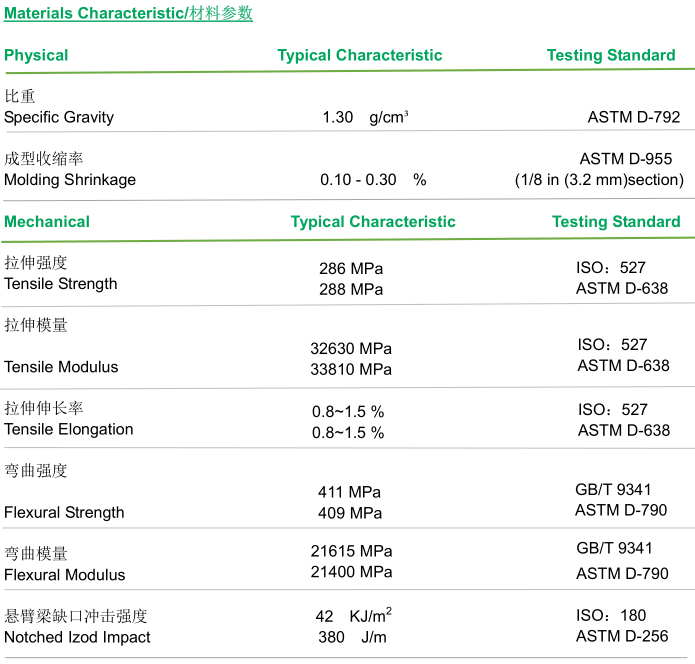

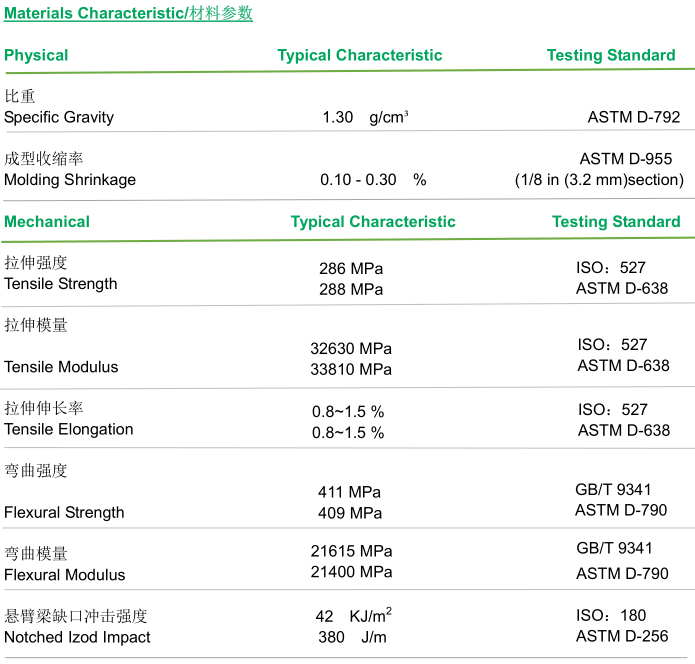

Product Datasheet

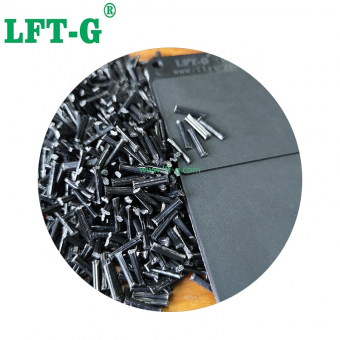

Product Images

The color is natural black or customized as requested. Fiber length ranges from 5–25mm. Other requirements can also be discussed.

Product Application

Carbon fiber (CF) is an excellent reinforcement material with high strength, high modulus, heat resistance, electrical and thermal conductivity, damping, shock absorption, and noise reduction properties.

With its light weight and high strength, PA66 reinforced with carbon fiber is widely used in aerospace, automotive, high-speed EMU transportation, wind turbine blades, bridge construction, building materials, sports and leisure products, and many other fields as a dual-use emerging material.

We Can Offer You

-

LFT & LFRT material technical parameters and leading-edge design

-

Mold front design and recommendations

-

Technical support for injection molding and extrusion molding

System Certification

-

Quality Management System ISO9001 / IATF16949 Certification

-

National Laboratory Accreditation Certificate

-

Modified Plastics Innovation Enterprise

-

Honorary Certificate

-

Heavy Metal REACH & ROHS Testing

e-mail

e-mail English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português العربية

العربية 日本語

日本語 한국의

한국의 中文

中文