-

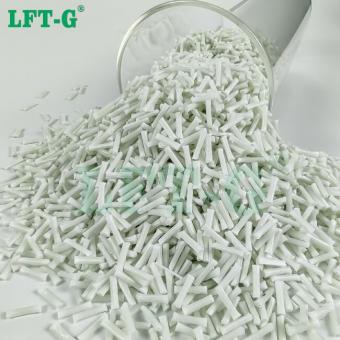

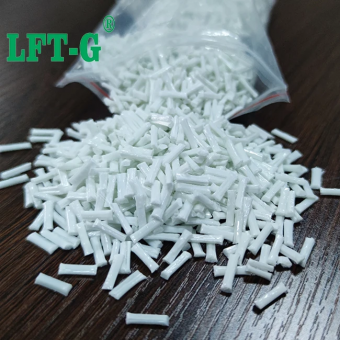

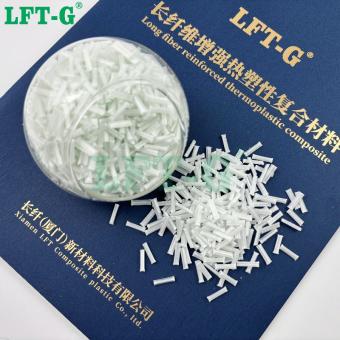

Green Material PLA Composite Pellets with 20-60% Long Glass Fiber ContentPLA long glass fiber reinforced material combines the biodegradability of PLA with the high strength and rigidity of long glass fibers. It offers enhanced mechanical properties and dimensional stability, making it ideal for eco-friendly applications requiring durability and performance.

- polylactic acids

- polylactic acid pellets

- polylactic acid material

- polylactic acid bioplastic

- biodegradable polylactic acid

- polylactic acid pla

Tags :

-

High Density Polyethylene Composite Pellets with 20-60% Long Glass Fiber ContentHDPE long glass fiber reinforced material provides improved stiffness, strength, and impact resistance, making it suitable for demanding applications. It is widely used in automotive components, industrial containers, and outdoor equipment that require durability and lightweight performance.

- high density polyethylene

- fiber glass density

- high density polyethylene tube

- high density polyethylene uses

- high density polyethylene polymer

- high density polyethylene properties

Tags :

-

PBT Composite Pellets with 20-60% Long Glass Fiber ContentPBT Long Glass Fiber Reinforced Material offers excellent dimensional stability, high strength, and outstanding chemical resistance. It is ideal for structural components requiring durability, heat resistance, and long-term mechanical performance.

- polybutylene terephthalate resin

- pbt plastic

- plastic resin manufacturer

- glass fiber reinforced plastic

- engineering plastic

- long glass fiber

Tags :

-

ABS Composite Pellets with 20-60% Long Glass Fiber ContentABS long glass fiber reinforced material offers enhanced strength, impact resistance, and dimensional stability, making it ideal for demanding structural applications. With its excellent processability and toughness, it is widely used in automotive, electronics, and industrial components.

- glass fiber reinforced polymer rebar

- glass reinforced polymer

- abs plastic material

- abs meaning material

- material abs plastic

- abs material properties

Tags :

-

Polyphthalamide Composite Pellets with 20-60% Long Glass Fiber ContentPPA long glass fiber reinforced material combines exceptional heat resistance, mechanical strength, and chemical durability. It is ideal for precision components in automotive, electrical, and industrial applications that require stability under extreme conditions.view more

-

Polyphenylene Sulfide Composite Pellets with 20-60% Long Glass Fiber ContentPPS long glass fiber reinforced material delivers outstanding thermal resistance, mechanical strength, and chemical stability. It is ideal for high-performance applications in automotive, electrical, and industrial sectors. This material ensures long-term reliability under extreme conditions.

- polyphenylene sulfide plastic

- glass fiber reinforced polymers

- fiber reinforced plastic sheet

- glass reinforced plastic properties

- polymer pps

- plastic pps

Tags :

-

Polyamide 12 Composite Pellets with 20-60% Long Glass Fiber ContentPA12 long glass fiber reinforced material offers exceptional strength, lightweight performance, and excellent chemical resistance. Ideal for demanding applications, it ensures superior dimensional stability and impact resistance. Perfect for automotive, electrical, and industrial components requiring durability and precision.

- polyamide polymer

- polyamide 12

- glass fiber reinforced nylon

- nylon fiber uses

- polyamide 6 12

- fiber reinforced composite materials

Tags :

-

TPU Composite Pellets with 20-60% Long Glass Fiber ContentTPU long glass fiber reinforced composite offers excellent flexibility, enhanced impact resistance, and long-term durability under dynamic stress. It is ideal for applications requiring both toughness and structural integrity, such as power tools, sports equipment, and industrial components.

- polymer manufacturer

- sole tpu

- tpu plastic

- plastic polymer sheet

- plastic components manufacturer

Tags :

-

Nylon 6,6 Composite Pellets with 20-60% Long Glass Fiber ContentPA66 long glass fiber reinforced material offers excellent mechanical strength, high thermal stability, and outstanding dimensional stability, making it ideal for demanding structural applications. It is widely used in automotive, electrical, and industrial components where durability and precision are critical.

- glass fiber

- pa66 material

- glass fibre reinforced polyamide

- polyamide polymers

- density polyamide

- nylon fiber properties

Tags :

-

Nylon 6 Composite Pellets with 20-60% Long Glass Fiber ContentLong glass fiber reinforced PA6 offers high mechanical strength, excellent heat resistance, and superior dimensional stability for demanding engineering applications. The addition of long glass fibers significantly enhances its stiffness and durability compared to unfilled PA6.

- nylon gf

- nylon 6 reinforced

- fiber glass stakes

- glass fiber manufacturer

- fiber glass companies

- pa6 datasheet

Tags :

-

PP Composite Pellets with 20-60% Long Glass Fiber ContentLong glass fiber reinforced PP offers excellent impact resistance, lightweight strength, and dimensional stability, making it ideal for structural and automotive parts. The integration of long glass fibers greatly improves mechanical performance compared to standard polypropylene.view more

-

LFT Polyetheretherketone Long Carbon Fiber Filled CompositesPEEK long carbon fiber reinforced material delivers exceptional mechanical strength, high temperature resistance, and superior dimensional stability, even under extreme conditions. The addition of long carbon fibers significantly boosts its stiffness and fatigue resistance, making it ideal for aerospace, automotive, and medical applications.

- peek polyetheretherketone

- peek fiber

- carbon fibre peek

- carbon filled peek

- peek carbon fiber filament

- peek carbon fibre

Tags :

e-mail

e-mail English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português العربية

العربية 日本語

日本語 한국의

한국의 中文

中文