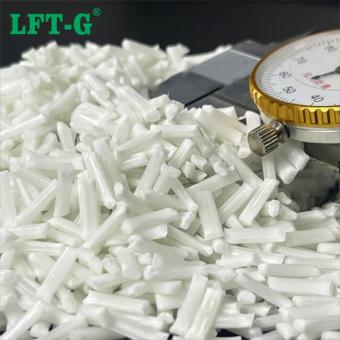

Long glass fiber has high strength, high rigidity, corrosion resistance, harsh environment suitability and low cost. When the resin matrix is impregnated and extruded into pellets ,Also called Long Glass Fiber Polymer it has good mechanical properties.

-

LFT Nylon 12 Polyamide plastic Long Glass Fiber Filled Composites pelletsPA 12 (also known as Nylon 12) is a good general-use plastic with broad additive applications and is known for its toughness, tensile strength, impact strength and ability to flex without fracture. PA 12 has long been used by injection molders due to these mechanical properties.

- High impact strength Injection molding

- modified thermoplastic resin LFRT

- structural parts car gears and bearings

- versatile engineering plastic

- polymers manufactuer of China factory price

- good price plastic resin PA 12

Tags :

-

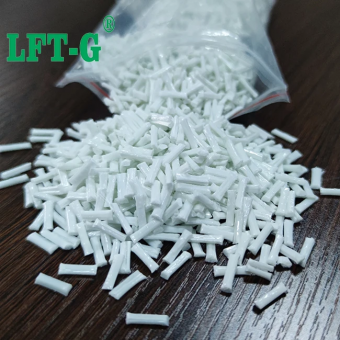

LFT Modified Polyamide 66 filled long glass fiber compoundsLong glass fiber reinforced nylon 66 has better reinforcement effect and dimensional stability, and the rigidity, tensile, bending, impact resistance and fatigue resistance of the manufactured products are better, and the service life is longer.

- Low warpage electronic appliance

- self owing pa66 pellets thermoplastic resin

- high strength and high toughness reinforced pa66 pellets

- best long glass fiber pa66 lgf30 granules

- PA66 6 twin screw lgf pellets

- Long Fiber PA66 granules Application

Tags :

-

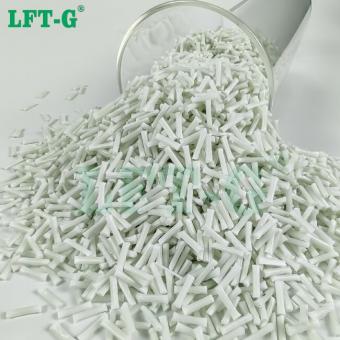

LFT-G Polyamide6 nylon6 filling long glass fiber orginal color for automotive partsThe main advantages of nylon 6 are its stiffness and resistance to abrasion. Moreover, this material has excellent impact strength, wear resistance, and electrical insulating properties. Nylon 6 is a highly elastic and fatigue-resistant material, meaning it will return to its original proportions after being distorted by tension. This polyamide is non-toxic and can be combined with glass or carbon fibers to increase performance.

- Polyamide 6 composite properties

- lgf thermoplastic resin good price

- High impact PA6 instead metal plastic

- injection molding plastic gf30 filter

- pa6 filling long glass fiber customized

- Reinforced plastic lightweight compounds

Tags :

-

Xiamen LFT-G Homopolymer Polypropylene reinforced Long Glass Fiber compondsHPP is Homopolymer polypropylene. These processes produce homopolymers for several industries including: automotive, packing, medical, consumer goods, and food containers. Within these industries, the homopolymers' corrosion resistance makes them ideal for containers, tanks, and pipes. Its dimensional stability allows it to be used for gears and bearings.view more

-

LFT Polypropylene PP filling long glass fiber 20%-60% high performance thermoplastic resinIn the manufacturing industry, in order to match some output products that require higher quality than usual, manufacturers will mix into PP plastic with glass fiber or glass beads. These two different forms of glass enhancement are inherently tough and durable, so when mixed, glass-filled polypropylene materials become lighter and stronger.view more

-

Glass Fiber Reinforced MXD 6 Nylon Resin Pellets Injection MoldingThis material combines high-density polyethylene (HDPE) with long glass fibers for enhanced mechanical strength, impact resistance, and dimensional stability. It is ideal for structural applications requiring durability, lightweight, and chemical resistance, commonly used in automotive, industrial, and outdoor products.

- mxd6-gf40

- nylon mxd6

- mxd6 polymer

- thermoplastic resin suppliers

- heat resistant nylon

- lightweight composite

Tags :

-

Glass Fiber Reinforced PBT Resin Pellets Injection MoldingAdding glass fiber to PBT is a commonly used method to enhance and modify PBT. The bonding force between glass fiber and PBT resin is good. After adding a certain amount of glass fiber to PBT resin, it can not only maintain the original advantages of PBT resin such as chemical resistance and processability, but also greatly improve its mechanical properties and overcome the problems. PBT resin notch sensitivity.view more

-

Glass Fiber Reinforced PLA Resin Pellets Injection MoldingPLA itself is an environmentally friendly thermoplastic, known for its biodegradability. However, it has limited mechanical properties, such as strength, toughness, and heat resistance. By incorporating long glass fibers, the performance of PLA is significantly improved, making it suitable for demanding applications.

- pps plastic

- long-fiber thermoplastic composite solutions

- metal replacement solutions

- pla plastic pellets

- thermoplastic glass fiber composite

- thermoplastic gfrp

Tags :

-

Glass Fiber Reinforced PPS Resin Pellets Injection MoldingLFT®PPA-NA-LGF is widely used in space aviation, chemical, electronic appliances, mechanical, automobile, railway fields etc. It can be used to make elements where high temperature resistance, electrical insulation are all-important in aviation; anticorrosion valves and electrical insulating parts; precise plugs; parts of engines, terminal etc.

- pps glass fibre

- pps plastic melting point

- pps raw material

- pps plastic uses

- pps polymer melting temperature

- pps composites

Tags :

-

Glass Fiber Reinforced PPA Nylon Resin Pellets Injection MoldingFiber-reinforced PPA has high temperature resistance, high strength and low density, so it is considered the best resin to replace steel with plastic in the future. It can be used in many industrial and civil fields, including automobiles, equipment, entertainment, food processing, communications, electronics and electrical , power tools, gardening, etc.view more

-

Glass Fiber Reinforced PE High Density Resin Pellets Injection MoldingThis material combines high-density polyethylene (HDPE) with long glass fibers for enhanced mechanical strength, impact resistance, and dimensional stability. It is ideal for structural applications requiring durability, lightweight, and chemical resistance, commonly used in automotive, industrial, and outdoor products.view more

-

Glass Fiber Reinforced ABS Resin Pellets Injection MoldingAfter adding glass fiber to ABS, the rigidity, heat resistance and dimensional stability of the composite are significantly improved. In addition, the cost performance of ABS plus glass fiber is extremely good, which can meet the needs of manufacturers while reducing costs.

- abs plastic melting point

- abs plastic pellets

- abs granules manufacturer

- natural abs color

- abs glass fiber compound

- abs raw material

Tags :

e-mail

e-mail English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português العربية

العربية 日本語

日本語 한국의

한국의 中文

中文